By Troy Ivan

ibc@ichibancrafter.com

Finding the most simple, safe, clean, and desirable way to decarb has been a passion I’ve been chasing for a few years now. Chopping through all the misinformation is very confusing for someone new to the concept of decarb, as well as those that have been doing it for decades. We are turning those decades of bad information upside-down with this simple process that’s already used in a variety of applications. I’m not creating something new here but utilizing tech others already use. I’m happy because it’s crazy easy; I’m unhappy because it’s taken me forever to stumble onto something so simple. For those unfamiliar with primary decarbing considerations and traditional processes, please see my previous post, DECARBOXYLATION (DECARB) 101.

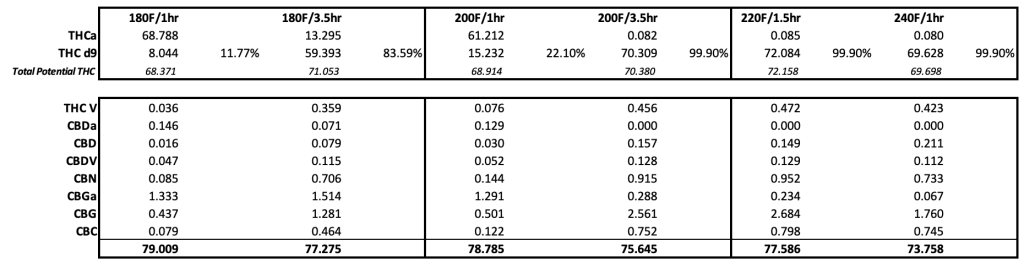

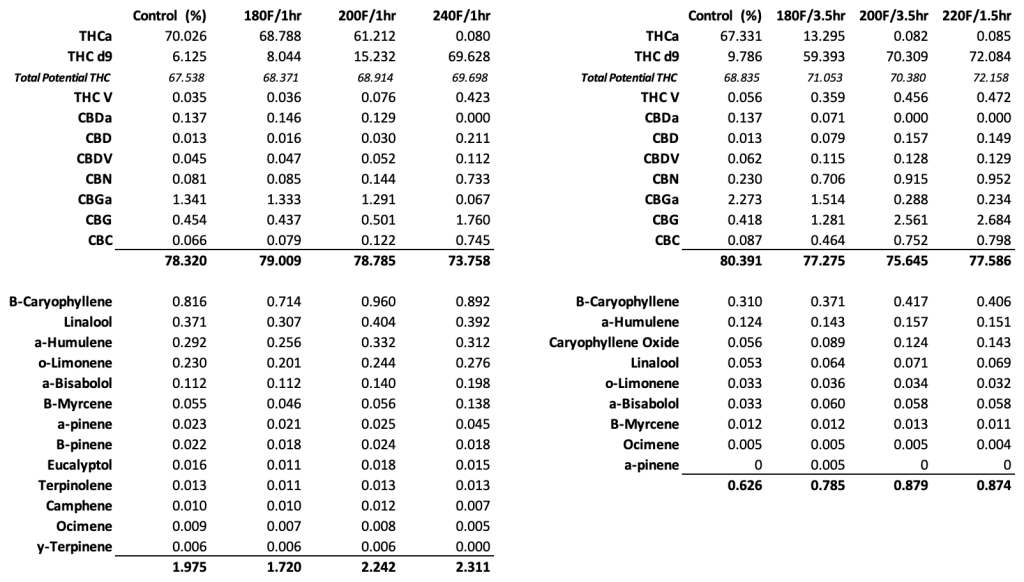

I’ve used the term “jar tech” in a few posts for CWD, making sauce and sugar wax, and pure EHO carts. The term simply refers to using a jar as a vessel to achieve an end goal. In this post, I’m explicitly presenting the results of using jar tech for decarbing only. The testing data shows the terpenes in the control samples without decarb remained in every subsequent decarbed sample.

This process is essential because most traditional home decarb processes ruin a concentrate’s flavor and aroma, negatively impacting any product using the concentrate. Additionally, those decarb processes burn off the vast majority, if not all, of the terpenes that may have been present. Jar tech decarb can solve both of those problems. Now, words like “full-spectrum” can be accurately applied to fully decarbed cannabis oil where they weren’t true before. If you start with a beautiful extraction and then decarb using jar tech, the aroma and quality of the oil will be unbelievable.

SIMPLE PROCESS

The process is straightforward and only requires a jar and a heat source. Unfortunately, the smallest quality canning jars are 4 oz, so I used a sample size of 20 g of oil at a time to fill the jar about 25%, which seemed like a good amount to test with. Other jars, containers, and volumes may work; I just don’t have time to try them all.

It’s important to note that I only work with clean extractions. I don’t work with, nor encourage people to work with, heavy black plant material-laden extractions. All results and exercises in this post used clean oil bound for edibles, produced with cold-temperature ethanol extraction, filtered well, and nicely purged. Oil that isn’t filtered well, contains a lot of plant matter or has substantial residual solvents may act very differently.

The general process idea is that an extract in a jar can decarb without the valuable terpene profile being blown off, oxidized, converted, or degraded. I cannot provide an in-depth scientific breakdown, but I can offer an idea of what I think is going on with this process. When heat is applied to decarb, a few things happen: breaking off the carboxyl group to “decarb,” terpenes evaporating, and oxidation. While decarb is a factor of temperature alone, terpene evaporation points change with pressure, and oxidation depends on abundant oxygen (mostly). What happens in our favor with the jar tech is that as heat applied to the sealed jar forces decarb to happen, it also increases pressure inside the jar, making it more difficult for terpenes to evaporate. There’s no free flow of oxygen, so large amounts of oxidation is avoided. Ultimately, we have glorious, terpene-rich oil that’s as decarbed as much or as little as you choose.

Step 1: Load jar

I loaded each 4 oz canning jar with approximately 20 g of well-purged oil and sealed it. Excess residual solvents in a heated, sealed jar can be hazardous, so only well-purged oil was used.

Step 2: Choose time and temp

The temp/time combinations I chose may appear to be incredibly ad hoc, and in reality, they probably are. Still, I wanted to establish various data points from which I could make reasonable assumptions. I have partial, complete, and overly-done conversions that allow us to reasonably estimate the rest by applying this information to standard decarb knowledge. I’m not a fan of imperfect data and assumptions, but living under oppressive testing regulations handicaps my efforts, and I work with what I have.

When looking at this data, an essential factor is how long the entire material sample was up to temp. If you think about the samples I worked with and how they were introduced to heat, you should realize a couple things. Just because a sample was placed in a heated environment doesn’t mean the extract was at the desired decarbing temperature the entire time. Once a jar with 20 g of oil was placed in the heat, the jar, air in the jar, and the entire concentrate needed to come up to heat. The time for all those components to come up to heat is called the ramping time, or “ramp.” I estimated with the temps, jars, and concentrate volume being processed, a proper ramp would be 15-30 minutes. For example, the 180°F/1hr was probably only really at temp for about 30 minutes, so if I wanted a 1 hr decarb, I would have to add the ramping time of about 30 minutes and increase the total time exposed to heat to 1.5 hrs. Every case will be different and require the decision to add ramp time or not depending on concentrate volume and surface area.

Recommended Temp/Time

Decarb temp and time combinations are nearly infinite because it’s a sliding scale so these recommendations are not set in stone but a good place to start.

For carts (no ramp included): 180°F/1 hr, 200°F/45 min

Full decarb (no ramp included): 200°F/2 hr, 220°F/1.5 hr, 240°F/1 hr.

Step 3: Choose heat source

Choose a heat source that fits the desired time and temp. The temps involved here can be achieved in several ways: sous vide, Instant Pot, oven, steam, and a double boiler. People will ask if they can use the Ardent to do this? The answer is yes, you probably can with some assumptions about temps, and only if you already have one; for God’s sake, please DON’T go out and buy one of those for decarbing; it’s silly.

Step 4: Load jar then place in heated environment

I’m only comfortable using good quality, brand canning jars, so I’ve restricted my experimentation to those. I like to work with the jars about 25% full. After putting the concentrate in the jar, I sealed it and placed it into the pre-heated environment of choice. It’s that easy.

Bubbles will appear while the oil is in the heated environment, and decarb is progressing. The bubbles will not be a reliable indication of when the decarb process is mostly complete, like with the decarbing of oil in open atmosphere. The pressurized environment in the closed jar represses the release of CO2 bubbles, much like carbonation in a capped soda bottle. The best approximation we can use for the completion of the process is what we know about the time vs. temp combinations for decarbing. It’s not perfect, but it’s the best we have to work with.

*Working with glass in changing temp environments and pressures can be hazardous, so caution and appropriate hand and eye protection are required.

Step 5: Remove from heat and allow to cool

After the allotted time, remove the jar and allow it to cool naturally on an appropriate heat-resistant surface. Opening the jar prematurely can enable some terpenes to evaporate if it is warm enough. A lighter, or even transparent, higher cannabinoid layer may settle on the bottom. Once the jar is completely cooled, it can be opened and stirred to homogenize the oil as much as possible. When the concentrate is stirred, there can be a neat, foaming release of CO2 bubbles, like opening that soda bottle. It’s fun to watch, but be careful because it will expand and may overflow if too full. If it foams up, I set it aside for a while after stirring, and when all the bubbles settle, the oil is ready to be used!

TERPENE RETENTION DATA

Two sets of testing were performed with different starting materials and terpene profiles. An interesting point to remember is that as decarb takes place, terpenes represent a slightly higher weighting as cannabinoids lose weight. Some of these samples were purposefully under or over-processed to see a range of results, but as far as the terps are involved, they are all in a pretty tight range, which is excellent news.

CONCLUDING CONSIDERATIONS

The preparation and execution of these posts require a great deal of time, effort, material, testing fees, and more. Steve Wenger stepped up and helped out with everything here. Without his help on this project, it would not have been possible. Thank you very much, Steve!!

Not being able to collect more data points and iterate these tests for more comprehensive and potentially accurate guidance is frustrating. Still, we do what we can with Colorado’s testing regulations as they are. With that in mind, I expect some changes and updates to this information and hope to refine the process and info down the road.

One pretty cool thing we can see is that in some samples that were probably over-processed with time and/or temp, the CBN levels are elevated, but the terpenes are still nicely represented. Obviously, with traditional heat application decarbing techniques and “decarbing appliances,” this hasn’t been possible. It seems that the testing indicates pretty high CBN conversion compared to CWD, and I’m not sure why, but it’s something to keep in mind. Before taking it too far out of context, realize it’s only a tiny amount of CBN conversion, and if you look at the “total potential THC” numbers, there was no discernible negative impact there.

I haven’t tested CBD with this method yet, but I suspect it will align with all other CBD and THC comparisons we’ve seen previously. Almost every time, at a chosen temp, CBD takes twice as long as THC. Until we come up with comparative data, I will be simply doubling the time I would typically use for THC and calling it a day.

Lastly, this post is only a report of our testing, not a recommendation for anyone to use at home. There are hazards when working with sealed, heated glass heating sources, especially if residual solvents are not well purged. Anyone attempting to replicate this process does so at their own risk and is encouraged to use all applicable safety precautions.

I HOPE THIS WAS INFORMATIVE AND YOU ENJOYED, STAY LIFTED FRIENDS !!

CHECKOUT THE IBC EXTRACTION LOUNGE GROUP ON FACEBOOK

Thanks again for the detailed experiments and well written results. I do have an Ardent FX (which I got for an unbelievable $100) but I’m going to try your technique for cart oil.

Hi Ichi, another great post. Thanks again for all the time and effort you put into this.

A few quick questions if I may, with the development in post ethanol recovery “Jar Tech” for decarbing are you no longer completing a “CWD” on the extraction before ethanol recovery?

What is your experience with viscosity differences between CWD and Jar Tech? I recently completed a very clean wash and used CWD for 3 days (full decarb) then recovered the ethanol. After completing the final purge I was left with a very high quality extract that split out with a clear cannabinoid layer (it looked incredible and smelt even better). The layers were then mixed together but had a very high viscosity. I managed to get some of the the extract into a ccell cart but due to the high viscosity it doesn’t “flow” well. Even after being left for weeks the cart doesn’t draw well.

Have I taken my final purge too far? Would “Jar Tech” yield a better viscosity result? It’s wonderfully terpy but is not usable in carts in its current form.

Any guidance would be greatly appreciated.

Sounds like you are doing right. The concentrate will set up very tight if purged well but that should still work well in carts as long as you are using good CCELL carts.

I would like to specifically know how to decarb using my instapot. Im very new to this and last time used my oven. Reading your percentage rates after decarbing in the instapot, ut seems like the way to go!

It’s just temp and time. They are the same pretty much regardless of the appliance being used

Thank you so much for the detailed experiments and write up. Essentially, do the extraction with non decarbed flower, and decarb the oil, right? I have tried a variation where I extract, mix in the MCT in a 1 ounce bottle and then decarb @260 for an hour. I wonder if this is comparable. Would take me a while to get 20g of oil with the little machine, if you consider doing this again, I wonder if it would be possible to test with a smaller amount.

I have decarbed in MCT and it has worked. I just haven’t been able to test it properly. My guess is that that should work very well but only guessing at this point.

Amazing. Thank you so much for sharing. Will be trying soon.

When you apply the jar lids and screw on the bands, are you screwing the bands on tight, or using the standard canning technique of placing the lids on and screwing the bands on lightly (like the reclaim jar on the EtOH)? Thanks!

Tighten to seal

Gotcha!

So you are heat purging oil before decarb’ 🤷🏻♂️

Not sure what “heat purging” is. Ethanol extraction and low temp ethanol recovery at around 100F then decarb oil.

Awesome blog! I like experimenting with different extraction/infusion method.

Now, I think you should do a blog entry on decarb and extract in oil, all in one shot. There are many good reasons, I think, to that method. 1)Terpenes will infuse directly into the oil. 2)Way quicker and cleaner method.

I have been doing it like this with the Instant Pot. Ground weed in mason jar barely covered in mct oil. Tighten the lid. The whole jar goes into the Instant Pot with water level up to the oil. Set the IP to 80 minutes at high pressure. Keep Warm for 30 min. The results have been good but I am not 100% whether the timing is good for optimal decarb, extraction, and infusion.

This post says optimal IP decarb (without oil) is 240F (IP High pressure) for 1hr and I have been decarbing for 40 min. I will increase my decarb according to your recommendation. Now, with the decarb and infusion in oil in one shot, I increase the time to 80 minutes since weed in oil takes a long time to come to temperature. What I’ve noticed is when I take the jar out, I can still see bubbles which is indicative of CO2 boiling off/decarbing still. Perhaps I should go to 100 minutes next time and see.

I think it would be super optimal to do both decarb and infusion in oil, all in one shot using the Instant Pot. Just need to find the optimal time.

Yes, this is all mostly correct. The problem is I’m not a fan of working with infusions and this is such an easy thing for anyone to try and to test that it’s not really something I’m looking to spend my time on. If you see the information in this Jar Tech post it lends itself pretty closely to supporting decarb in the carrier oil. I just don’t like working with infusions because, 1) they are relatively low potency 2) they have a large volume of carrier oil, hence the potency 3) you are stuck with the oil 4) efficiency is pretty unreliable 5) the ramp time to bring a large jar of carrier oil up to temp is pretty substantial as is the cooling time. So, yes, what you are saying is correct, it’s just not something I’m interested in.

Yeh, for sure with infusion the potency is not that high due to the large amount of mct oil required to cover the ground up biomass/plant material.

Ethanol extraction is very nice with that ExtractCraft machine in order to recover costly alcohol.

However, if one wants to be even more economical in creating highly concentrated tincture or other forms of concentrates then I think for a home user using dry ice and bubble bags in order to produce kief which can then be used as starting source material which is much more economical than the ExtractCraft machine and ethanol.

It’s actually it’s not. Harvesting kief is highly inefficient and leaves a ton of material behind. If you look at my post on the rosin, hash, and EtOH ecosystem you can see how they fit together. So, your supposition about the economics is actually incorrect. If you haven’t actually tested it you might come to that conclusion, but it is wrong. Ethanol on the other hand is much more efficient and is still only around the 80% mark or so. Dry sifting, bubble bags and any kiefing will never be as efficient as ethanol extraction.

Wow really? I for sure didn’t know that ethanol extraction is much more efficient than harvesting kief. It’s just common sense from observation and some experience harvesting kief would make me make that assumption when comparing cost of the materials/devices required to make extractions.

Well, what if one grows and does not care much about the most efficient extraction method but rather upfront cost of extraction devices like the ones from ExtractCraft? From this point of view, then harvest kief would suffice as starting material for making concentrates.

I still have many more articles on your website to go through and am actually reading up on that “ecosystem”.

No. 1) with ethanol extraction you have pretty much pure oil when made properly with a very high degree of efficiency. 2) With harvesting kief, your kief is still at best 50% cellulose from the trichome heads. 3) If you go after a big yield making kief you are going to have a ton of impurities included in the kief making it more dirty as well as add to the cellulose non-oil component. What you are calling “common sense and experience” seems to be only centered around YOUR experience and not the overall reality of various forms of extraction. You are also looking at things differently than I do. You are simply thinking about the “cost” of equipment, I look at value. If you think about what you wrote here it really makes little sense in the big picture of things. Yeah, if you don’t care about the value of what you are throwing away because you grow so much then that’s your prerogative. However, if the value of what you are throwing away is more than the cost of the equipment would cost to preserve that value, then the cost of the equipment has VALUE. I don’t really care if you buy the ExtractCraft equipment or not, but the way you are looking at the value is a bit myopic. The fact of the matter, like most of my writing suggests, all of the different types of processing and uses have their advantages and disadvantages. Personal preference and end goal is a big part of it they decisions people will make, education and unfettered understanding and knowledge of the big picture is what allows people to make those decisions wisely. If you would like to discuss further please discuss in the Ichiban’s Extraction Lounge group, there are many members there that would be happy to discuss further with you.

What would you recommend for a person who is new to ethanol extractions to determine that they’ve purged all of the ethanol out after the exact craft?

For jar tech using a vac chamber for purging is good. If you don’t have then simply air purging until mostly stable should work.

Is the vac chamber you mentioned different from the vacuum oven in your articles?

They do the same thing. You can google each to see the difference

Thanks because little concerned about decarbing if there’s any ethanol left in the mixture

I see you mentioned partial decarb at 180 for like 1 hour but I also read (not your articles) 150 for 24 hours. It’s a sliding scale but those are really far apart. Maybe the 24 hr one was for rosin.

They are on curves, not linear

My first attempt/experiment with my new source and instant pot. I have about an oz of oil. Next is full decarb. For 20 oz, you decarb at 240* for an hour. Will too long of a decarb hurt the final product? What would be your best guess for time for this amount? Thanks, great fun!

It depends. You don’t want to decarb any longer than necessary because any additional exposure to heat increases risk of decline of quality. Luckily, within a reasonable range you won’t really know. It’s all about temp, not volume, so as long as you get everything up to heat evenly the time is the same.

thanks.

Another question on decarb. You indicated decarb continues no matter what over time for ~ two years to full decarb. I realize there are many variables, so,,, I have some pot from a friend who grows “good stuff”. Its vacuum sealed bud which I kept in my frig, 0*F for 9 months. Any suggestions on decarb? Again this is my first attempt, so experimentation is good, but no need to screw up if possible. But no matter, education is not free.

How about throwing it up in my group for discussion?

Hello, How did you analyze your product ?

I am looking for a way to analyze my extraction but cannot find a good way to do this.

Thank you for your research that help a lot.

Are you referring to the lab testing?

Yes, I am referring to the lab testing. The one that gives you the concentration of each molecula (THC, THCa, CBD, …)

Sorry, I’m just unclear what you are actually asking. I had the samples lab tested and the lab provided the results. If you are asking how you can get lab testing done, the best way would be to find someone with lab testing offered as a service in your area.

Hi Ichi, not sure if this blog is still active, but I have a (most likely silly) question. When you say you start with a clean extraction, do you mean doing something like a golden dragon but with a dried (not decarbed) flower, and then evaporate the alcohol until you end with the oil and then do the decarbing using the jar as per this post? If yes, is evaporating the alcoholto get to the oil using the jar and slow cooker method still possible or will that impact the terpenes as well?

Really like your blog, very informative, but sometimes I get lost in the jargon.

Using open air evaporation will typically decarb in the process and also blow the terps. To see how you can do the extraction and recovery properly to make clean oil the process is in my Ethanol Extraction: Complete Breakdown article and for best equipment checkout the DIY articles

Amazing site and info and videos, great work, thank you! Just getting started into this world and it’s fascinating

I want to make concentrated tinctures for sublingual use with ethanol, for recreational use and to help me with anxiety and depression.

I’d love to setup a DIY vacuum distiller like yours, but I can’t do it at my current place for several reasons. Best I can do right now for the purge step is to use an induction stove and a fan outside the house.

Any tips you would share with a newbie trying to do this?

Thanks in advance 🙂

Welcome to the fray! I don’t really have tips for the traditional open-air evaporation.

Would it work and be safe done in an air-fryer?

I’m not sure how low air fryers go in temp. If the container is closed airtight, and the temp is in the right range, it should work.

Hi Ichiban, great resource and I appreciate it a lot. I wanted to ask how this technique has held up in terms of safety over the years. I understand the ideal gas law is vastly insufficient to describe the CO2 supersolution likely created during a sealed decarb in a fixed volume, but the napkin math indicates a very, very high pressure – well beyond what’s considered safe for canning jars. Do you have any insight on the “real” pressure experienced in a sealed jar tech decarb? Has anyone done an experiment with a pressure valve to get a reading? I have run 2 batches with 4g extract to 56ml volume headspace and no apparent issues, but I would like to get a better idea of safety before I continue. That 4g of extract is generating up to around a half gram of CO2! That’s a lot of potential pressure and I don’t want a pipe bomb going off in my oven. Thanks in advance for any potential information!

I haven’t heard of a single issue yet. It’s easy to check though, just release the cap at the end and see how much pressure there is.

There is one possible large problem with your calculation and reasoning. You say there is “That 4g of extract is generating up to around a half gram of CO2!” Here’s my question. Is it really being generated, or, is it already there?

There are a lot of people using the tech in the IchiBan’s Extraction Lounge group on FB. You can make a post in there and ask the members and get a lot of feedback.

Lastly, as I mentioned in the Jar Tech Decarb post, as well as the Closed Wash Decarb post, these are not processes that should be taken lightly, and if anyone decides to perform them, it is at their own risk, and strict safety measures and protective gear must be used.