By Troy Ivan

ibc@ichibancrafter.com

Today, everyone is hypnotized by light color extractions, even though color alone does not determine quality. Clarity, cleanliness, aroma, terpene content, and potency are important quality considerations. It’s possible to have a high-quality concentrate that’s dark in color or a low-quality concentrate that’s light in color, so the deliberation shouldn’t be over what color the concentrate is but why it’s that color. This post is to help those who have or maybe make dark concentrates for the wrong reasons and provide a reliable process to improve product quality.

Everyone has had a wash or end product that came out darker, more green, or containing more undesirables than they hoped or intended. Questions on dealing with dark concentrates and extractions come up daily. The easy answer is to take more care early in the extraction process and avoid picking up undesirables in the first place. As we all have experienced, sometimes it’s too late to avoid, and you need to clean up a dirty extract. The easiest way for us to do this at home is to scrub the extract with carbon. Doing so will lose some desirable components along with the undesirables, inadvertently removing cannabinoids and terpenes, so a decision must be made. Do you accept the dirty nature of the current extraction or polish it and sacrifice some of the desirables? To help crafters make this decision, this post will explain a simple way to perform the polishing, using activated carbon powder for scrubbing to lighten the color and diatomaceous earth for very fine filtering, provide a side-by-side comparison of polished and unpolished results from the same extraction, and look at what was lost in the process.

MATERIALS AND WASH

I used decent quality trim and 190-proof food-grade ethanol to make the wash. The trim and ethanol had been in the freezer for several days and were between -2° F and -10° F. To get the green wash I needed, I did a 1-hour freezer wash to get some green pickup without going to a full FECO.

INITIAL FILTERING

The 1-hour wash initial filtering went through fine mesh coffee filters for plant matter separation, then through the Buchner funnel using 3-micron filter paper. The wash came out with the perfect amount of green and just over 1 L in volume.

SEPARATING TWO SAMPLES FOR COMPARISON

I separated two 300 ml samples from the 1 L of filtered wash. One sample would be processed as is, and the other would go through polishing. I will refer to the sample that will be processed without scrubbing as the ‘control sample’ and the other as the ‘polish sample.’ The sample size of 300 ml was used to match the capacity of the equipment used for the ethanol recovery.

THE CARBON SCRUB

The activated carbon is essentially charcoal and functions in the same way as a charcoal filter commonly used to purify water. Activated carbon powder is good at removing contaminants. However, it does this in an indiscriminate manner and is difficult to filter out of the wash due to the very fine particle size.

The carbon scrubbing process is nearly as easy as mixing the wash and carbon and shaking. The method is most effective if the wash is warmed to about 80F before adding the carbon. The recommended amount of carbon to use is about 5% of the estimated oil volume contained in the wash. For 300 ml wash, I estimated about 3 g of oil, so the recommended amount of carbon to be used was 0.15 g. I made an error here and added quite a bit more, about 1.5 g, but I proceeded and pretended not to notice. I originally planned to use a stir plate for agitation, but a friend with much experience advised that shaking provides much better results, so I put the wash and carbon in a small jar and gave it a good shake instead. That’s all there was to it, and the carbon scrubbing was complete, but the resulting wash was utterly black with carbon and required very fine filtering.

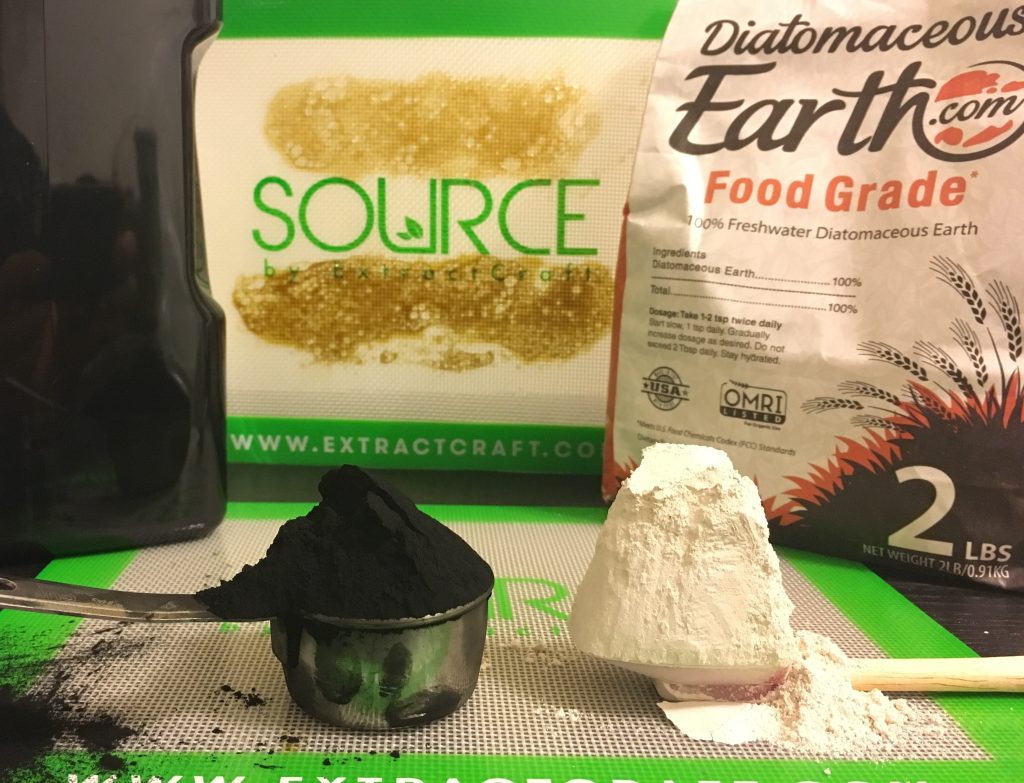

DIATOMACEOUS EARTH (DE) FILTER

Wikipedia defines diatomaceous earth: “Diatomaceous earth ( /ˌdaɪ.ətəˌmeɪʃəs ˈɜːrθ/) – also known as D.E., diatomite, or kieselgur/kieselguhr – is a naturally occurring, soft, siliceous sedimentary rock that is easily crumbled into a fine white to off-white powder.”

The DE is a very fine powder, almost like flour. When mixed with ethanol and properly filtered with a vacuum-assisted Buchner funnel, it forms a filter cake that makes for very fine filter media. I layered a Buchner funnel with a 3-micron filter paper, then a coffee filter on top of it to help hold the DE in place and form the filter cake.

To make the DE filter cake, I first stirred the DE and ethanol to create a slurry resembling a mud puddle. When the slurry is poured into the Buchner funnel, with the vacuum assist running, the ethanol is sucked through into the beaker, and the DE is left behind in a solid cake form.

The more you pour in, the thicker the cake will form. I don’t know, and can’t find information on, what thickness of the filter cake is ideal, so I made it about a 1/4-1/2 inch thick. I let the cake settle into a solid form and then began adding the carbon wash for filtering before the DE cake dried out.

The progress was quite slow, even with the vacuum assist from a large pump. It took about 5 minutes to filter 300 ml. This would have worked better if I had used one of the larger Buchner funnels. The slow progress was no real problem, but the 1 L size would have provided more filter surface area and better flow. That was a good lesson learned here and a point to remember.

The polish sample worked through the filtering layers and emerged in the beaker cleaned up and glorious. When the samples were set side by side, the improvement in color was obvious.

PROCESSING THE SAMPLES INTO OIL

The processing plan was simple. First, use low-temperature, vacuum-assisted ethanol recovery to separate the oil and reclaim the ethanol, then pop the oil samples into the vacuum oven to finish. I experienced a minor spillage mishap of the polish sample, so I evened the samples to 250 ml each for processing. Each sample ran separately in its own Source Turbo for about 2 hours, then in the vac oven overnight at 92° F.

RESULTS

The difference in the resulting oils was literally night and day, light versus dark. Both oils were very clear and clean. The darker oil carried over the green tinge from the wash, while the blond oil was pleasing to the eye.

Out of the vacuum oven, the purged end products finished as expected.

I knew polishing would improve the concentrate color, but I didn’t know what to expect regarding how much scrubbing would affect the yield or quality of the final product. Determining exactly how much oil was lost in the process was the most interesting part of the exercise. The control sample was obviously going to be heavier than the polished sample, but by how much? The control sample was 2.75 g compared to the polished sample at 2.26 g. The scrubbing and filtering reduced the final product yield by 0.49 g or 17.8%.

The dark, undesirable material was removed, and a small amount of terpene character was lost from the polish sample. The terpene profile was only marginally weaker, but the psychotropic effects were notably more potent than the unpolished extract. The darker extract was richer with terpenes and robust, but the green from the wash was identifiable by the plant taste.

FINAL COMMENTS

That was a lot of fun! I’ve wanted to do this project to determine if carbon scrubbing and the necessary advanced filtering are worth the hassle and yield sacrifice for a while. It is evident from the results that it works very well to lighten the color and increase potency. So, when are those benefits of better color and increased potency worth sacrificing the 17.8% in yield?

I wouldn’t bother scrubbing and sacrificing any desirables for edibles, tinctures, or topicals. I would instead opt for the benefit of maximizing yield over color, taste, and potency. The problems of color and flavor will be lost in a larger recipe or formulation. I would also not polish for vaping if the singular concern was a shade of color. If all other clarity, cleanliness, aroma, terpene content, and potency considerations are acceptable, I will keep it as is. We know from the blog post ‘Color and Cannabis Concentrate Quality’ that dark concentrates can be as good or better as lighter concentrates.

I will only recommend polishing if a wash inadvertently picked up green when not wanted or an already made concentrate has an unpleasant flavor. I highly recommend avoiding the problem from the beginning and exercising extra caution in carefully executing the wash, like in my blog post ‘Cannabis Oil QWET Extraction Battle of the Wash: Dry Ice vs. Freezer.’