By Troy Ivan

ibc@ichibancrafter.com

Today, everyone is hypnotized by light color extractions, even though color alone does not determine quality. Clarity, cleanliness, aroma, terpene content, and potency are important quality considerations. It’s possible to have a high-quality concentrate that’s dark in color or a low-quality concentrate that’s light in color, so the deliberation shouldn’t be over what color the concentrate is but why it’s that color. This post is to help those who have or maybe make dark concentrates for the wrong reasons and provide a reliable process to improve product quality.

Everyone has had a wash or end product that came out darker, more green, or containing more undesirables than they hoped or intended. Questions on dealing with dark concentrates and extractions come up daily. The easy answer is to take more care early in the extraction process and avoid picking up undesirables in the first place. As we all have experienced, sometimes it’s too late to avoid, and you need to clean up a dirty extract. The easiest way for us to do this at home is to scrub the extract with carbon. Doing so will lose some desirable components along with the undesirables, inadvertently removing cannabinoids and terpenes, so a decision must be made. Do you accept the dirty nature of the current extraction or polish it and sacrifice some of the desirables? To help crafters make this decision, this post will explain a simple way to perform the polishing, using activated carbon powder for scrubbing to lighten the color and diatomaceous earth for very fine filtering, provide a side-by-side comparison of polished and unpolished results from the same extraction, and look at what was lost in the process.

MATERIALS AND WASH

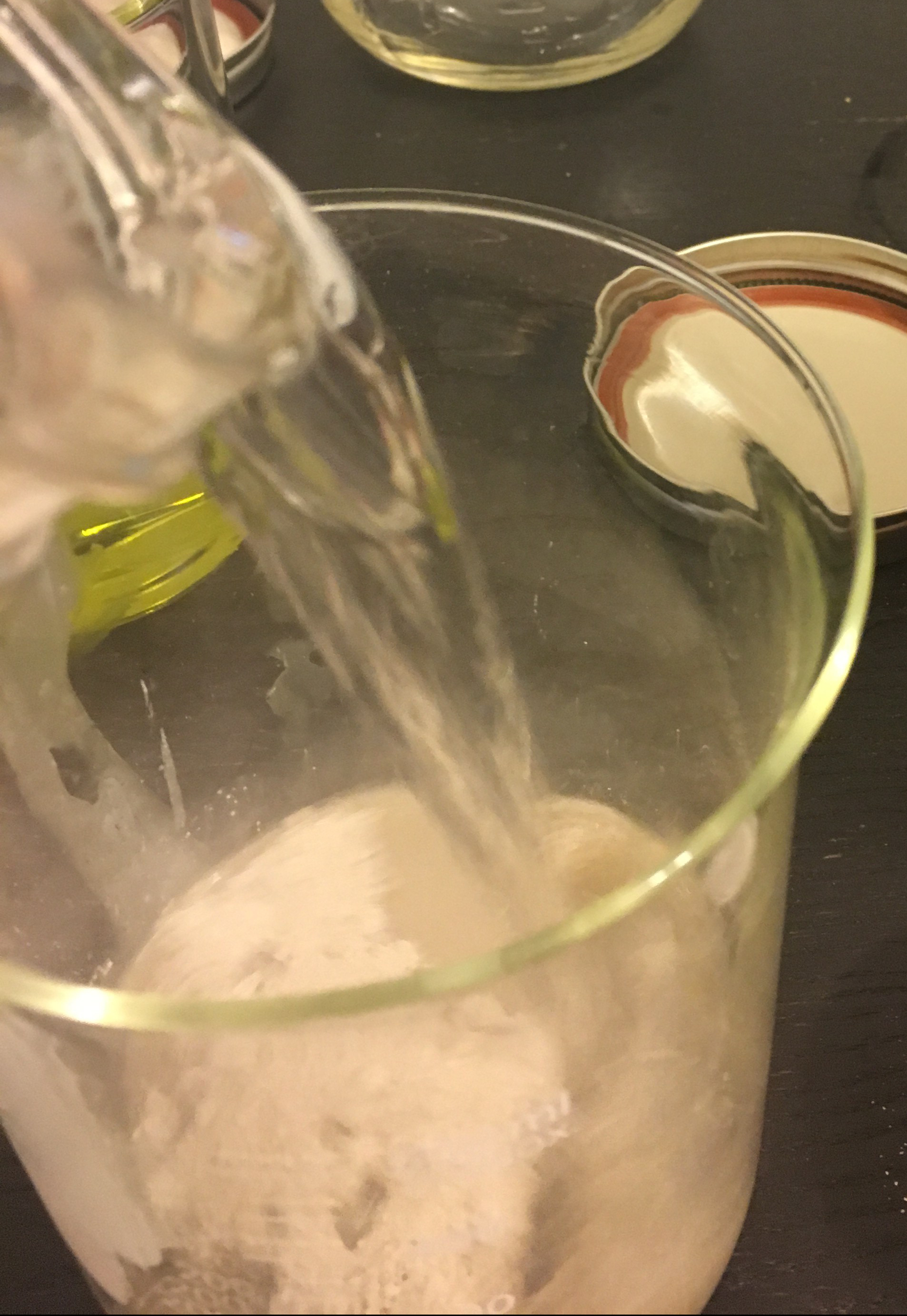

I used decent quality trim and 190-proof food-grade ethanol to make the wash. The trim and ethanol had been in the freezer for several days and were between -2° F and -10° F. To get the green wash I needed, I did a 1-hour freezer wash to get some green pickup without going to a full FECO.

INITIAL FILTERING

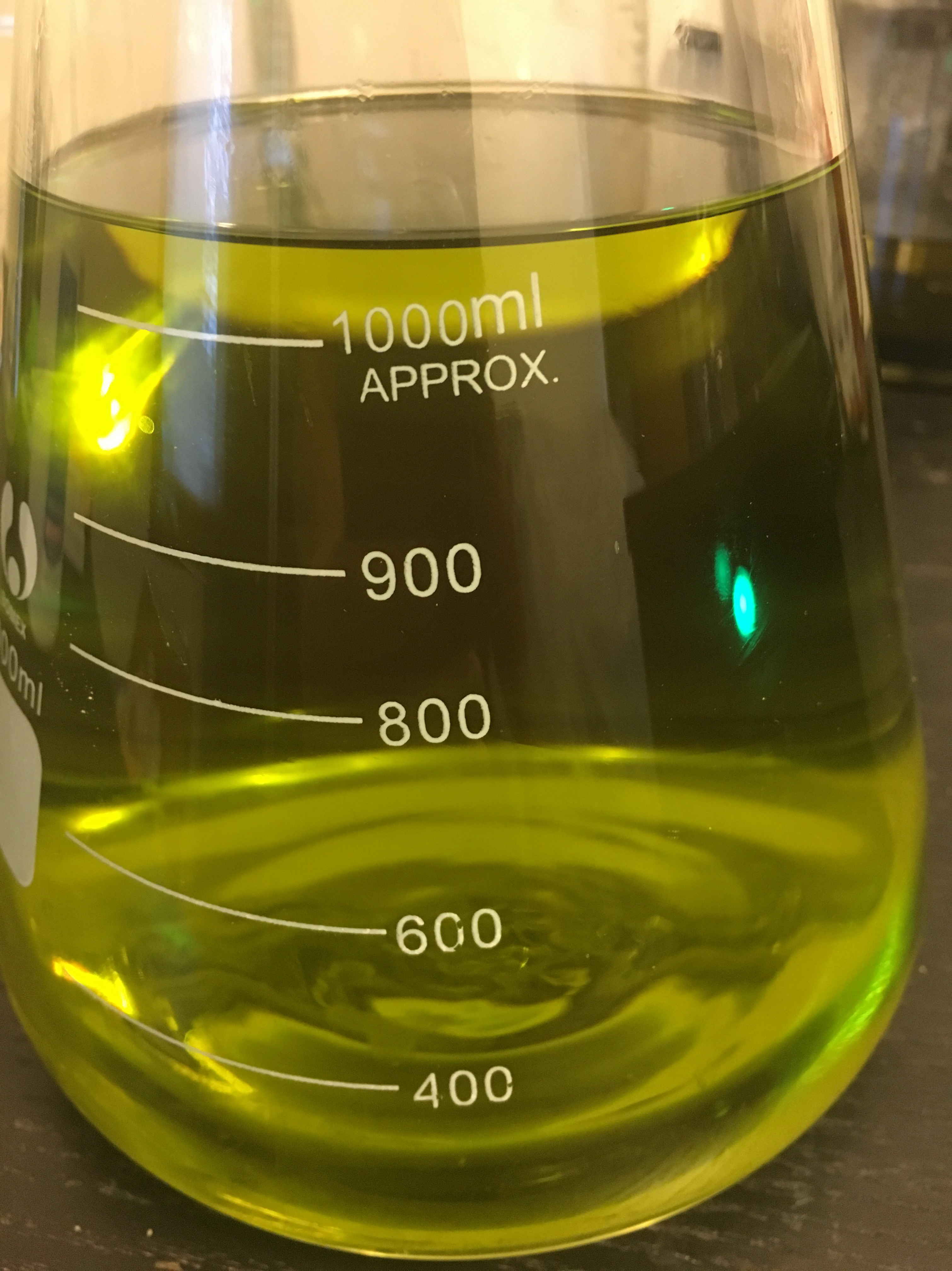

The 1-hour wash initial filtering went through fine mesh coffee filters for plant matter separation, then through the Buchner funnel using 3-micron filter paper. The wash came out with the perfect amount of green and just over 1 L in volume.

SEPARATING TWO SAMPLES FOR COMPARISON

I separated two 300 ml samples from the 1 L of filtered wash. One sample would be processed as is, and the other would go through polishing. I will refer to the sample that will be processed without scrubbing as the ‘control sample’ and the other as the ‘polish sample.’ The sample size of 300 ml was used to match the capacity of the equipment used for the ethanol recovery.

THE CARBON SCRUB

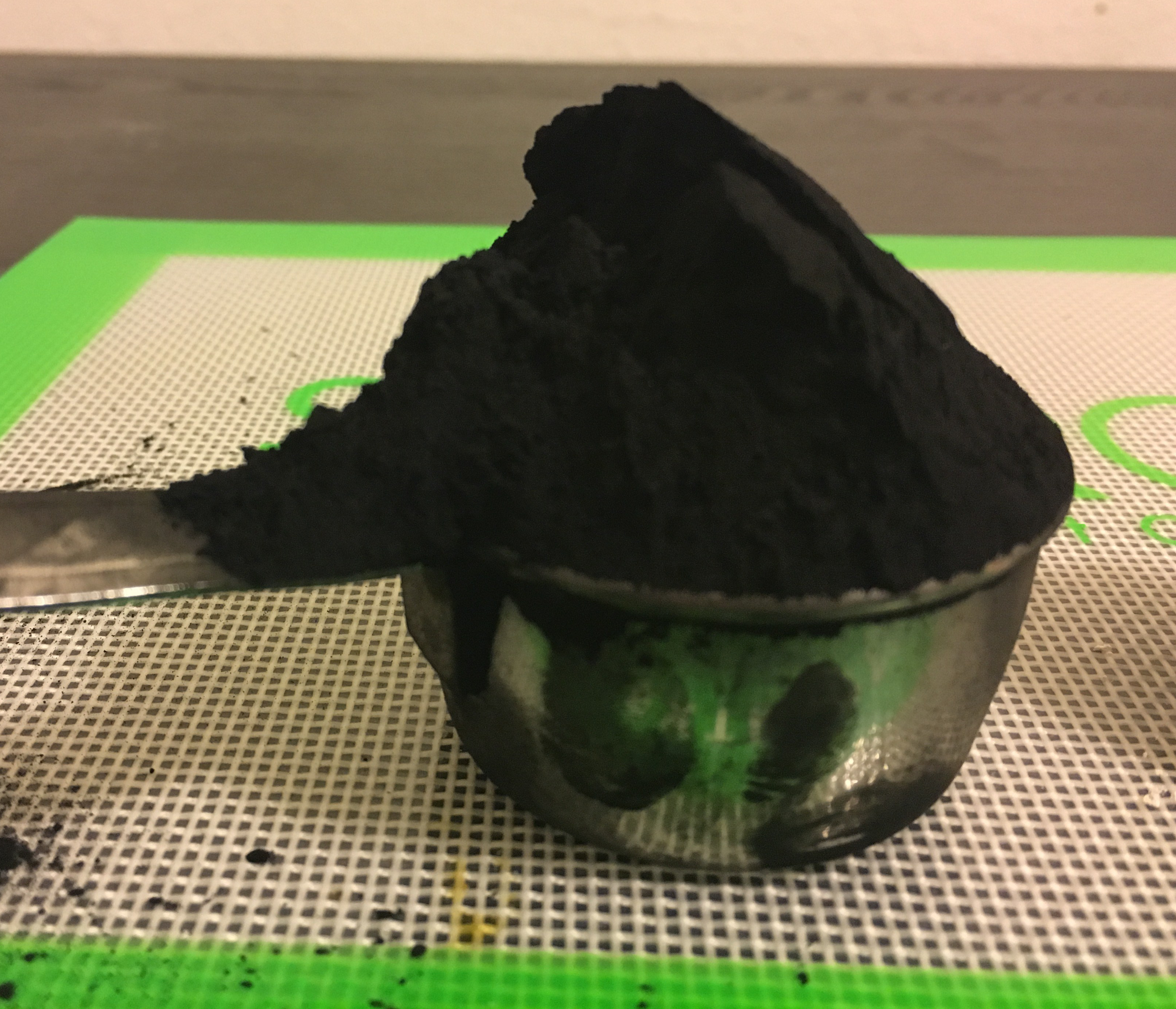

The activated carbon is essentially charcoal and functions in the same way as a charcoal filter commonly used to purify water. Activated carbon powder is good at removing contaminants. However, it does this in an indiscriminate manner and is difficult to filter out of the wash due to the very fine particle size.

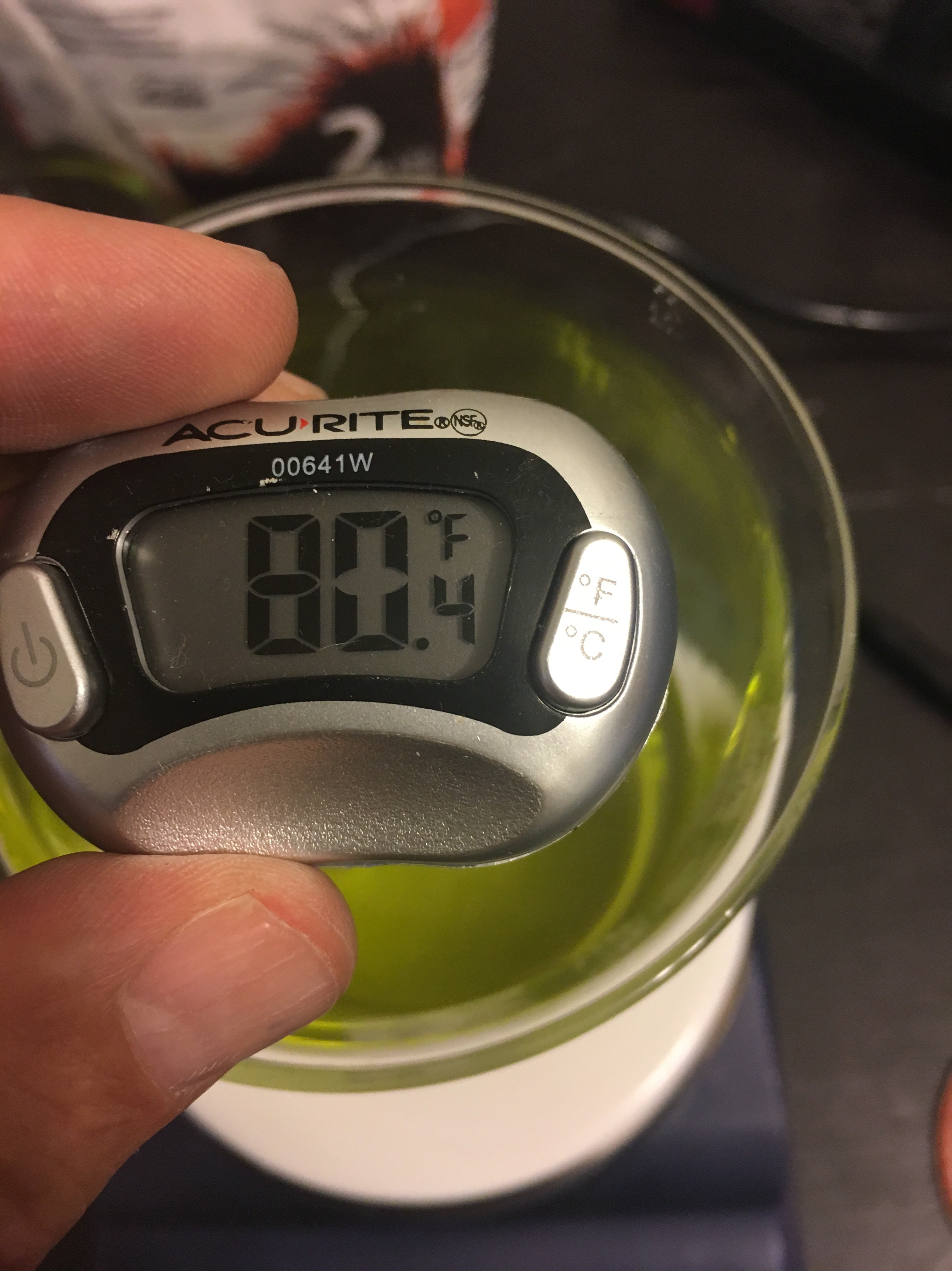

The carbon scrubbing process is nearly as easy as mixing the wash and carbon and shaking. The method is most effective if the wash is warmed to about 80F before adding the carbon. The recommended amount of carbon to use is about 5% of the estimated oil volume contained in the wash. For 300 ml wash, I estimated about 3 g of oil, so the recommended amount of carbon to be used was 0.15 g. I made an error here and added quite a bit more, about 1.5 g, but I proceeded and pretended not to notice. I originally planned to use a stir plate for agitation, but a friend with much experience advised that shaking provides much better results, so I put the wash and carbon in a small jar and gave it a good shake instead. That’s all there was to it, and the carbon scrubbing was complete, but the resulting wash was utterly black with carbon and required very fine filtering.

DIATOMACEOUS EARTH (DE) FILTER

Wikipedia defines diatomaceous earth: “Diatomaceous earth ( /ˌdaɪ.ətəˌmeɪʃəs ˈɜːrθ/) – also known as D.E., diatomite, or kieselgur/kieselguhr – is a naturally occurring, soft, siliceous sedimentary rock that is easily crumbled into a fine white to off-white powder.”

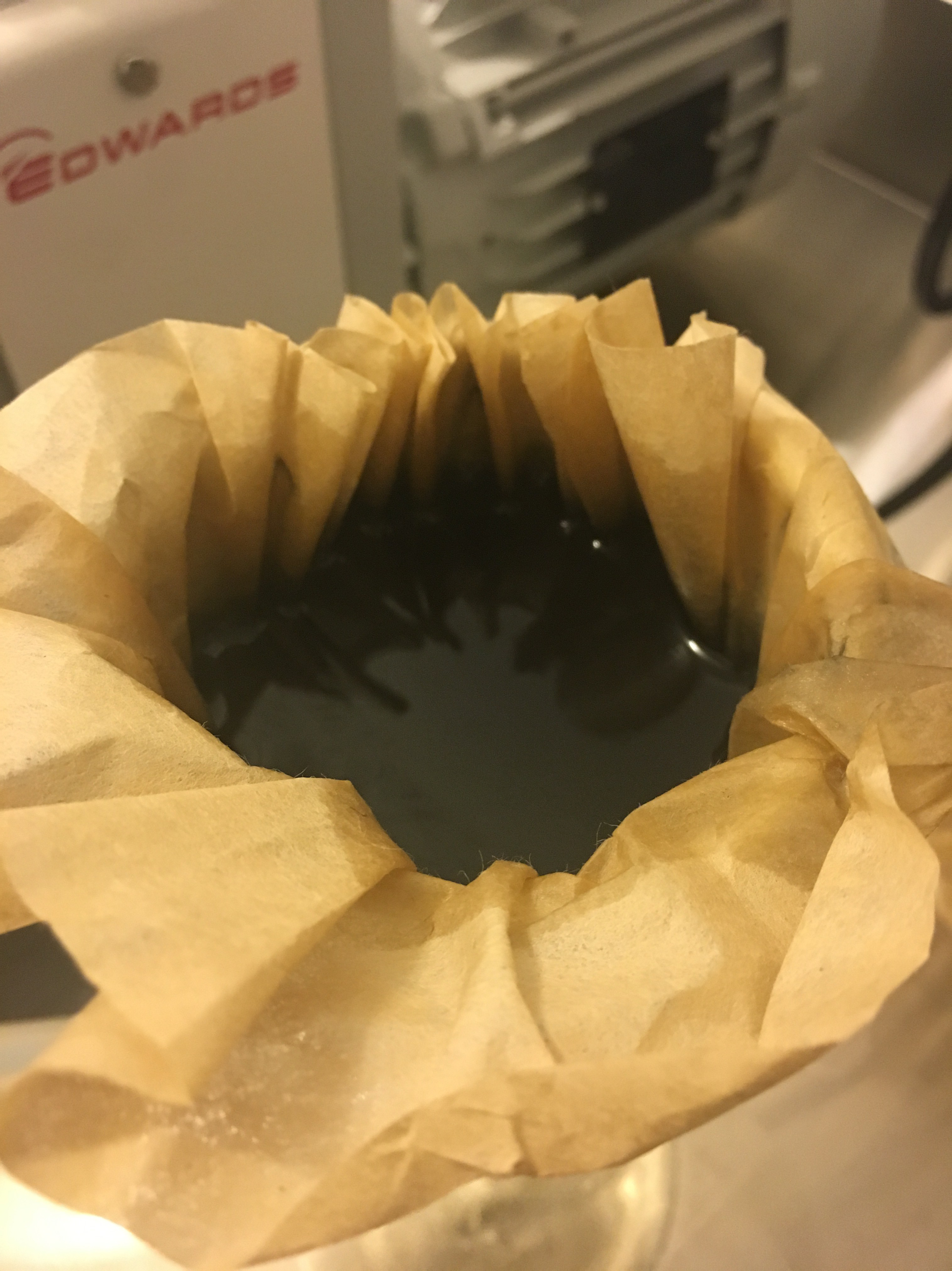

The DE is a very fine powder, almost like flour. When mixed with ethanol and properly filtered with a vacuum-assisted Buchner funnel, it forms a filter cake that makes for very fine filter media. I layered a Buchner funnel with a 3-micron filter paper, then a coffee filter on top of it to help hold the DE in place and form the filter cake.

To make the DE filter cake, I first stirred the DE and ethanol to create a slurry resembling a mud puddle. When the slurry is poured into the Buchner funnel, with the vacuum assist running, the ethanol is sucked through into the beaker, and the DE is left behind in a solid cake form.

The more you pour in, the thicker the cake will form. I don’t know, and can’t find information on, what thickness of the filter cake is ideal, so I made it about a 1/4-1/2 inch thick. I let the cake settle into a solid form and then began adding the carbon wash for filtering before the DE cake dried out.

The progress was quite slow, even with the vacuum assist from a large pump. It took about 5 minutes to filter 300 ml. This would have worked better if I had used one of the larger Buchner funnels. The slow progress was no real problem, but the 1 L size would have provided more filter surface area and better flow. That was a good lesson learned here and a point to remember.

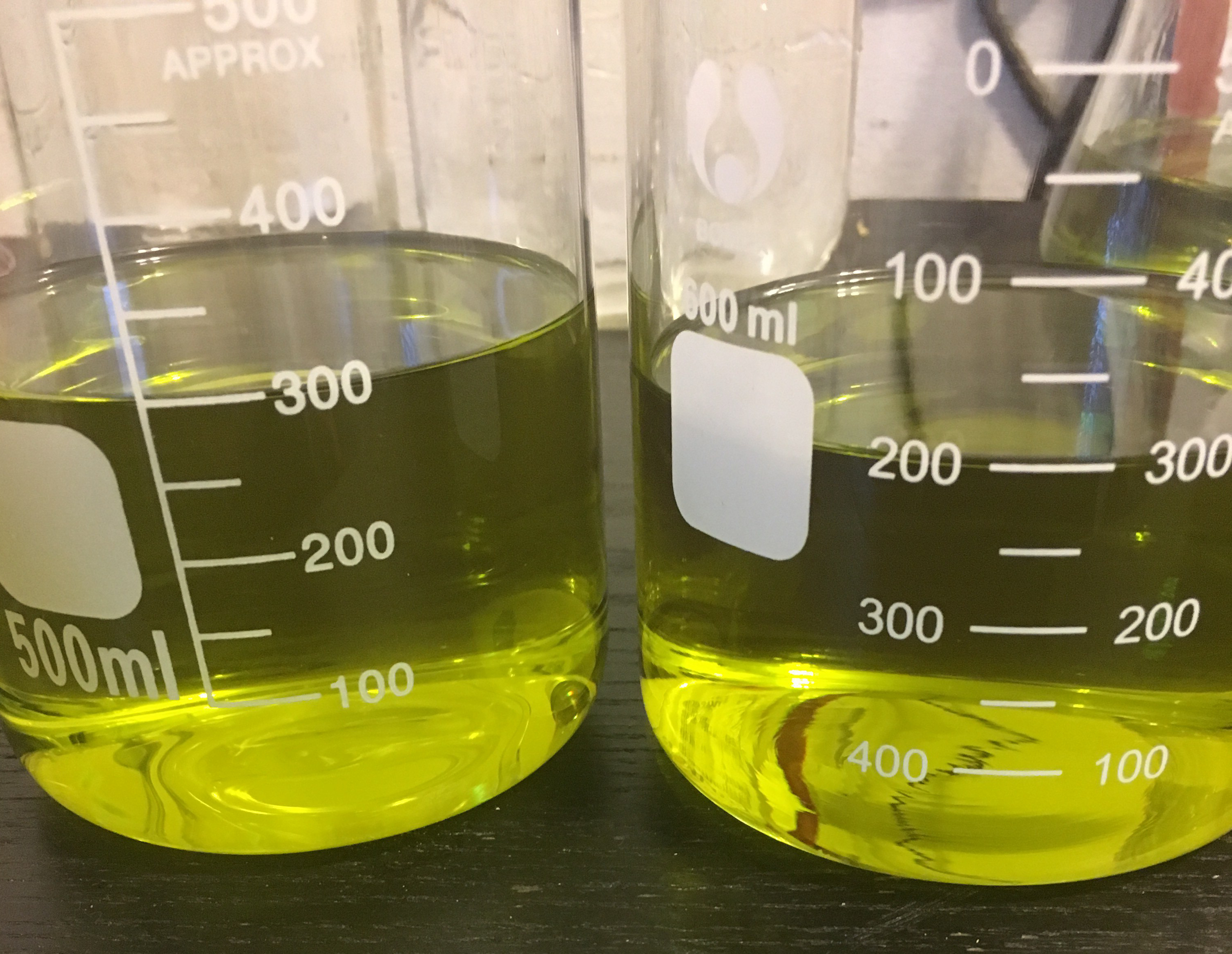

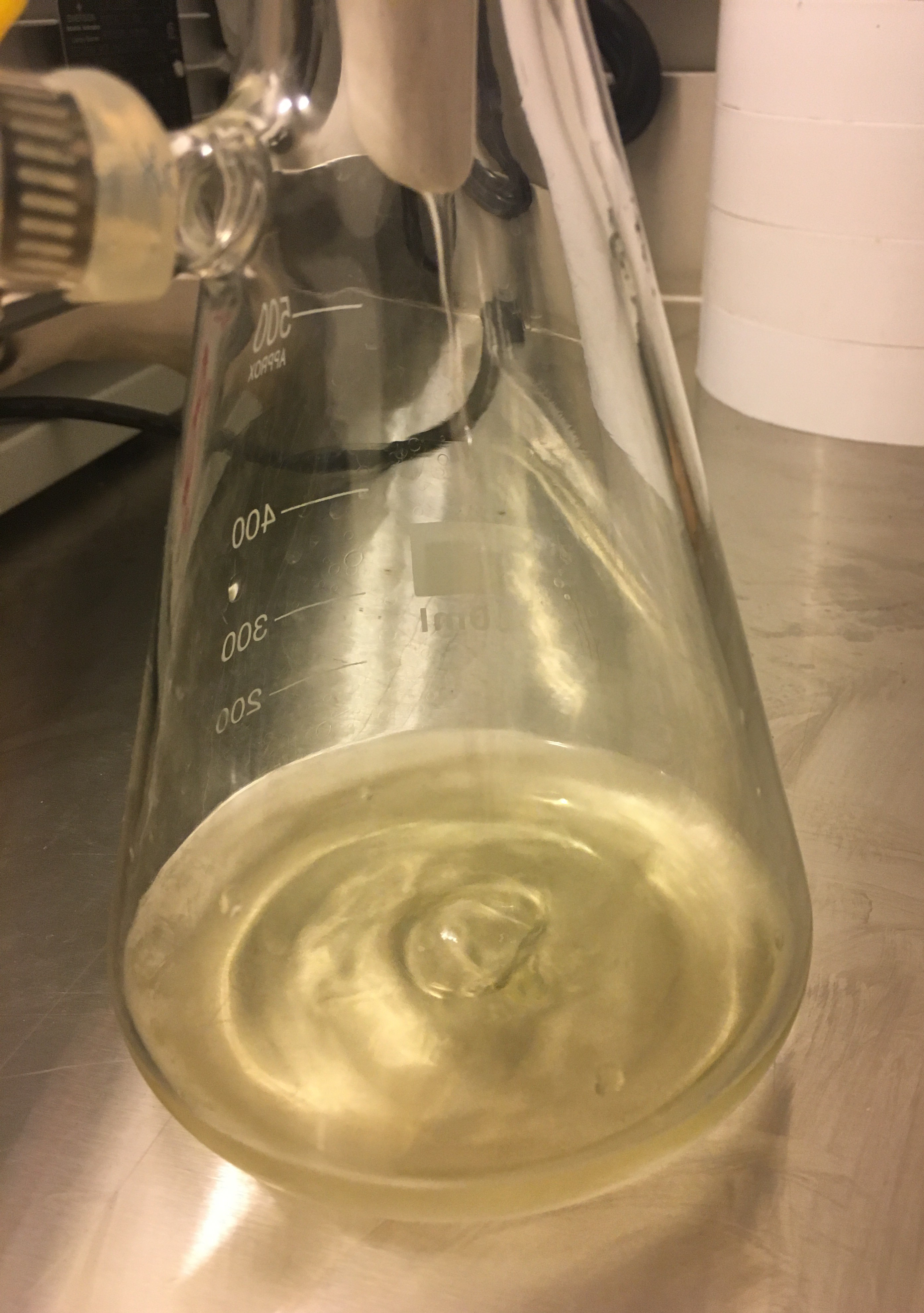

The polish sample worked through the filtering layers and emerged in the beaker cleaned up and glorious. When the samples were set side by side, the improvement in color was obvious.

PROCESSING THE SAMPLES INTO OIL

The processing plan was simple. First, use low-temperature, vacuum-assisted ethanol recovery to separate the oil and reclaim the ethanol, then pop the oil samples into the vacuum oven to finish. I experienced a minor spillage mishap of the polish sample, so I evened the samples to 250 ml each for processing. Each sample ran separately in its own Source Turbo for about 2 hours, then in the vac oven overnight at 92° F.

RESULTS

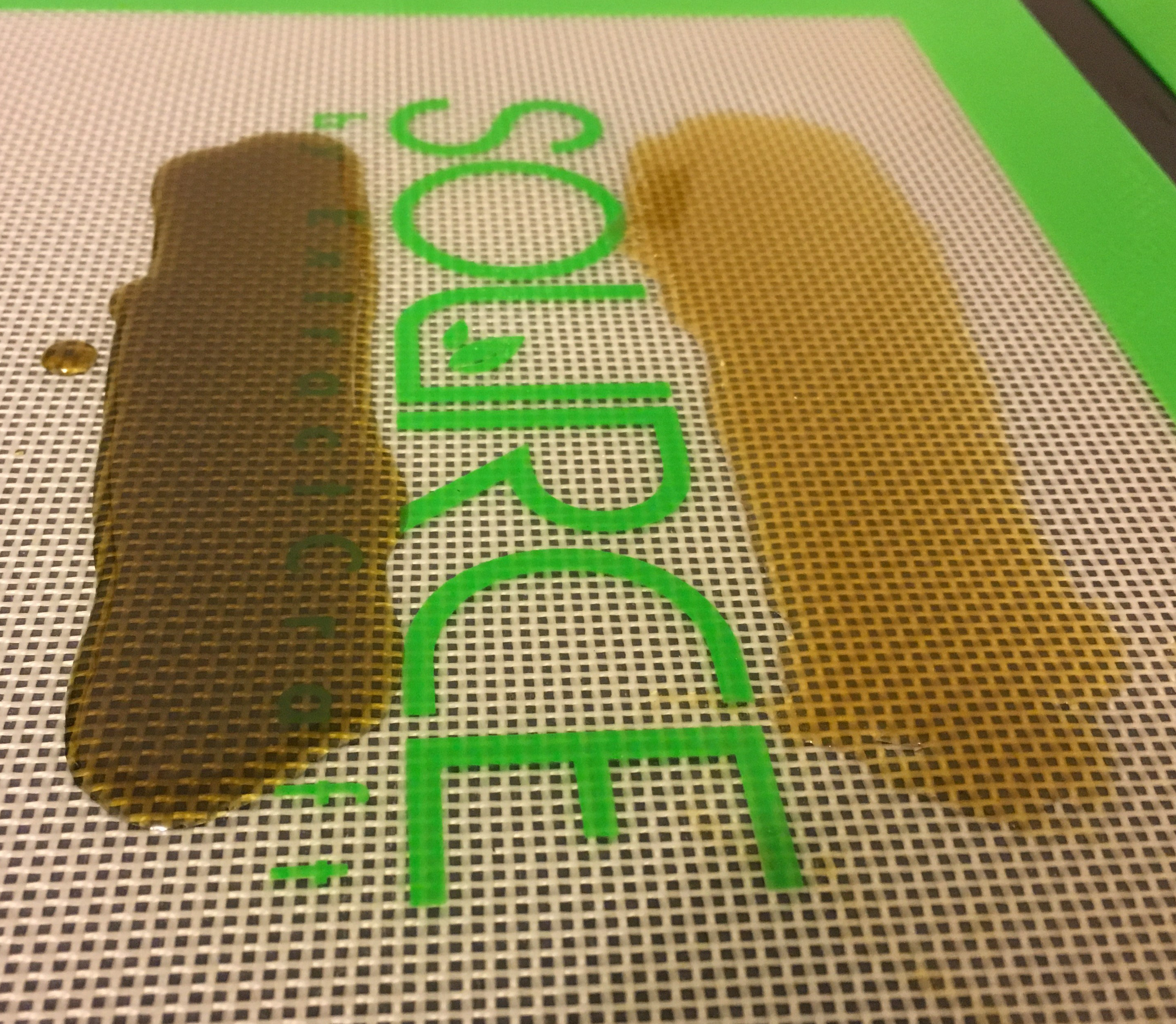

The difference in the resulting oils was literally night and day, light versus dark. Both oils were very clear and clean. The darker oil carried over the green tinge from the wash, while the blond oil was pleasing to the eye.

Out of the vacuum oven, the purged end products finished as expected.

I knew polishing would improve the concentrate color, but I didn’t know what to expect regarding how much scrubbing would affect the yield or quality of the final product. Determining exactly how much oil was lost in the process was the most interesting part of the exercise. The control sample was obviously going to be heavier than the polished sample, but by how much? The control sample was 2.75 g compared to the polished sample at 2.26 g. The scrubbing and filtering reduced the final product yield by 0.49 g or 17.8%.

The dark, undesirable material was removed, and a small amount of terpene character was lost from the polish sample. The terpene profile was only marginally weaker, but the psychotropic effects were notably more potent than the unpolished extract. The darker extract was richer with terpenes and robust, but the green from the wash was identifiable by the plant taste.

FINAL COMMENTS

That was a lot of fun! I’ve wanted to do this project to determine if carbon scrubbing and the necessary advanced filtering are worth the hassle and yield sacrifice for a while. It is evident from the results that it works very well to lighten the color and increase potency. So, when are those benefits of better color and increased potency worth sacrificing the 17.8% in yield?

I wouldn’t bother scrubbing and sacrificing any desirables for edibles, tinctures, or topicals. I would instead opt for the benefit of maximizing yield over color, taste, and potency. The problems of color and flavor will be lost in a larger recipe or formulation. I would also not polish for vaping if the singular concern was a shade of color. If all other clarity, cleanliness, aroma, terpene content, and potency considerations are acceptable, I will keep it as is. We know from the blog post ‘Color and Cannabis Concentrate Quality’ that dark concentrates can be as good or better as lighter concentrates.

I will only recommend polishing if a wash inadvertently picked up green when not wanted or an already made concentrate has an unpleasant flavor. I highly recommend avoiding the problem from the beginning and exercising extra caution in carefully executing the wash, like in my blog post ‘Cannabis Oil QWET Extraction Battle of the Wash: Dry Ice vs. Freezer.’

I hope this post provided some helpful insight and enjoyment. If you appreciate my work, please share and spread the word! Stay lifted, my friends !!!!

CHECKOUT THE ICHIBAN’S EXTRACTION LOUNGE GROUP ON FACEBOOK

I need some expert advice:

I cannot find high concentration THC to import into my country to help treat cancer. However, I can purchase without problem shatter/wax that contain at least 80% THC and I can buy locally 95% pure ethanol from a distillery.

The plan is to dilute the shatter into the ethanol and separate the solvent and impurities, such as butane, etc… from the THC while keeping the terpenes and any other beneficial components together…

This will be small scale production, mainly for my own use and it makes no sense to buy a full scale short path distillation set up. I can circulate refrigerated water through the condenser part and I have a heating source: what else do I need to make it all work?

Any suggestions??…

I’m not understanding why you would breakdown the shatter? What do you suspect is wrong with the shatter? Also, even low THC starting material will concentrate into high percentage concentrate….. What is your intended use?

He started with tain soup not shatter

One quick question

When you warm the wash to about 80F snd add the AC and agitate it, do you cool it back down with dry ice or cool it down with anything before pouring it into the funnel filtering through the DE cake?

80 is about room temp, goes straight to extraction

What is the mechanism for the filtering for the green leak, because the rate that you described is the flow rate for the filter media, which Whatman says that it flows at a 64 ml/min. Your rate was 5 minutes for 300 ml, in line with the Whatman specification, which gave 60 ml/min. So the controlling filter media appears to be the 3 micron filter since it is flowing per the specified rate. So what caused the chlorophyll to bind to the carbon and diatomaceous earth since it wasn’t acting as a filter media. It has to be a chemical bonding I would think instead of filtering….

With all due respect I have absolutely zero idea what any of that means

If the filter media is flowing at the stated rate for the filter media, about 60 ml/min for the 3 micron filter then if the diatomaceous earth was acting as a filter it has to be longer than the 5 minutes it took to filter the wash. 300 ml/60 ml is five minutes, the stated rate of the filter by most manufacturers of slow filters, which a 3 micron would be. So the flow rate was the same pre as well as post scrubbing. So I suspect that the process is a chemical process and not a filter process. Since it should take longer, and the filter media originally passed the green leak, what stopped it after scrubbing, since the filter was acting as it should and passing the wash at the same rate. Something is askew…

Have you tried any hydrophobic filters to filter out green leak…?!?

There wasn’t anything askew as far as I know. The 3 micron under vac is pretty fast, it obviously the DE that slowed the flow. What kind of hydrophobic filter? Molecular sieve?

Nice post. I see you had 1L after filtering. How much plant matter was required to produce that much wash? I’ve got a ounce of nice flower and a couple ounces of trim. The trim has been sitting in the freezer until I fired up the Source again. The flower has been in a black glass storage container with a couple small Boveda packets.

Would a food dehydrater work as a cheaper option to the oven you use? I can get a good waxy result if I leave it on the mat for a couple days, but not a hard shatter.

Instead of a stir plate, I’ve used a ultrasonic jewelry cleaner to mix dissimilar liquids with great results. Cheap on Amazon.

Hi Ron,

I ended up with about 1.2L. I’m not sure exactly how much plant matter was used in terms of weight. The photo in the blog is exactly what I used, the 2L jar with very fluffy trim, I’d guess about 2 oz or so. My focus was on comparable wash samples so didn’t bother with the weight of starting material because it wasn’t of interest.

The end result of what you have on the mat will depend on the strain itself, quality of filtering, quality of winterization, state of material, humidity, and such. Another problem I often see is people lay a think glob or line of concentrate on mat and expect it to turn to shatter and unfortunately it won’t, it needs to be very thin if using natural purging process.

With the carbon its not a matter of mixing to incorporate, but for scrubbing so the ultrasonic wouldn’t work well.

The dehydrator might be a stroke of genius, I’ll have to try it and think about it a bit.

I use a dehydrator like this one for drying clay when i’m working with jewelry design. It works great for that. It can run up to 70 degrees.

https://www.amazon.com/dp/B07DCS5NZ2/ref=cm_sw_r_oth_api_NscQBbJXNZ7MG

If the link doesn’t work you can just search on “food dehydrator” on Amazon.

I didn’t know if the vibration would help with the carbon, but it works great for salad dressing or e-juice.

Did you ever try the Food Dehydrator around 170 degrees F?

For what?

We discussed a food dehydrater when a vacumn oven is not available. I haven’t been able to retry it.

the comment right above this asks using a dehydrator instead of your vacuum oven to purge where you then reply this may be a stroke of genius and you may try doing that

Hi ron, I like the idea of a ultrasonic jewelry cleaner to mix things. Do you just place the glass? container in side the cleaner and let it run? I just read that you shouldn’t let the ultrasonic jewelry cleaner run dry for more than 30 seconds? curious?:)

Guys, I am keeping up with this – as I use extractors for food (vanilla extract and the like), if I want to dehydrate, don’t use heat – use a freeze drier from https://harvestright.com/ It will give you far, far better results, and you also end up with a good vacuum pump too (-;

(freeze drying removes all water using a vacuum at a low temperature – so more ‘goodness’ is preserved (-;

John

i just tried this, didnt really see any difference so far so . Both of the pics i took of the wash before and after look the same (dark brown/amber) how long did you soak the wash with the carbon? i used about 1.5g for 5oo ml as well…im gonna winterize now and then filter again time will tell thanks for this though..

For this I used about 2g or so of activated carbon for about 300 ml. With ethanol warmed to around 80F, and shook quite well for about 5 minutes? The effectiveness will depend on a number of factors; agitation, temp, how dirty the wash is, time exposed, etc.

After I do this, then I just filter it and run in the Source? Thanks much.

Yes, that’s correct

I noticed that it looks like you didn’t wash the filter cakes afterwards. You had 300ml of solution before filtering and about 250ml after. Couldn’t you have increased the yield by about 16% if you washed that lost solution out of the filter cake with clean ethanol? I’m also curious to see what the difference in color etc. would be using 0.15g of carbon like you intended since it would barely affect the yield.

I don’t believe washing the filter cakes would have resulted in anything consequential. I believe I mentioned the 50ml loss was due to a spill accident, if not I’ll have to go back and clarify. Using less carbon would have defiantly made a difference. Using too little also has the opposite effect, so if you are doing it for top performance you have to work with the same material and same wash a bit to find the perfect balance for each batch, its defiantly not an exact ratio for every wash. It’s going to range from 3%-10% and probably best around 5%-7% depending.

Would you recommend winterizing the wash before polishing?

Yes

I just did this method and it hands down worked 100%

Where did you get the carbon powder? I want to make sure I dont get too fine of powder. Im using a 3 micron funnel paper and the DE cake you described

I got from Lab Society

I used this method and it worked wonderfully a few times.

Right up until this last batch. I put too much carbon in it and it robbed me of most of my medicine. I started at 1g of concentrate and ended up with like 0.2g. I was careless with the carbon and too much got into it. Won’t do that again. I thought I’d share that piece of info with everyone else so they won’t make the same mistake.

Can you use iso instead of ethanol? Also, would Celite 545 be better than DE, or is there much of a difference.

Can use iso, I prefer ethanol for the food grade aspect. I was going to use Celite 545 but was told that for ethanol DE works better. Something to do with the polar component of the solvent, but not sure. If anyone knows I’d like to get schooled.

After you mix in the DE how long do you wait before filtering through the cake? Also, I used. 0.5g in 2000ml, at 75 deg. F. it cleaned it but not as much as unexpected when compared to the other jar not scrubbed yet. Is that way too little? I estimated may e 10 grams of oil so used half a gram. Does volume of wash come into play with amount if AC used? I may add 1g and scrub it again

Unfortunately, there’s no perfect measure, some experimentation may be required.

I have tried this over and over with no final product in good shape. The carbon scrub works, but I always end up with DE in the final product. After reclaim, I put it in my vacuum oven for 24 hrs. and it is VERY cloudy when I take it out. Any suggestions? What is the filter number you use. because Lab Society does not sell a 3 micron filter.

Thomas scientific slow flow is 3mu and they sell it. Im guessing you aren’t getting a good seal on the filter or you funnel has some residual contamination. You may need to move to a frit perk Büchner to make it easier?

Random that I found this thread! So A friend was discussing this weekend taking a water pitcher filter (brita/pur) and putting a layer of of carbon in the top area then running the wash through that.

Is this a poor man’s option? Does the carbon need to be stirred in to scrub or can the tincure/wash just be run through it as a filter?

Industrial guys have inline filters. Most britta filters are preheated with water which will ruin your wash. Its possible to put together a carbon filter, but its difficult to calibrate one for all occasions

Hi,

A couple of comments. If you want to carbon filter look at the filters and charcoal that can be purchased at home brewing shops (Thats what they are called in Australia). They work by percolation and the particle size of the activated carbon is easier to manage. Personally I don’t bother, it was extra work and too much loss. If I want the green colour or taste out I will water cure with rain water. I just let it soak in room temperature water and gently change the water every 12 hours. One 12hour rinse removes a surprising amount of green as well as dust, bugs and whatever. If you keep the process up for 5 days you can remove pretty well all the green and if smoked it has little smell and mild flavour. It looks like crap but is as strong as ever and gentle on the throat. After soaking you need to get the water out and dry without mould getting into it. I use a salad spinner, which cost a couple of dollars at a charity shop, to get the water out and gentle air flow in the drying room.

Another way to reduce green is to leave your jars of ethanol extract in the sun for a day or two before you reduce it to a concentrate.

problem with filters is the lack of control and that seems to be what you experienced with the large losses. Why water cure and take so long with so much hassle when you can use frozen wash processes? Have you had a chance to see my other blog posts for the super cooled qwet, or the dry ice vs freezer?

Hi,

Yes I have read your other articles and have used both methods at times. I live in the country and to get dry ice I have to make it which is not real cheap and is a bit of fussing. I have found a good chest freezer to be easier. I water cure mostly when making an oil which my wife uses to make chocolates and in cooking. I just don’t like the taste of green. I grow organic in soil and like to wash my product after it has been harvested so to me it is not a lot of extra work to put it in water. If you have never washed weed after you have harvested, it can be a bit of a surprise how much unwanted mater can be on the plants. My processes are not so time critical that a few days longer to wash or water cure are relevant. Water cured weed looks like crap but can make for very smooth weed for smoking or vaping or cooking. I will normally air cure smoking weed for up to six months before I store it anyway. I have never been satisfied with the poor yields from QWET processes, I like to get as much out as possible so if I am doing a cold maceration extraction I have left product for up to 6 months in the freezer when making FECO for capsules or suppositories. TO make a quicker FECO extraction with maximum strength I use a conical percolator with heat blanket and will winterise before concentrating. I found your trial interesting and I am of the opinion, based on my experience and things I have read over the years, that QWET extractions when done in a freezer at less than 10 degree F can be left for an hour without picking up a lot of colour but will give a better yield. It would be interesting to see a proper trial that fully tested all the variables of time temp and yield. I suppose a lot of it gets down to what you like or your customers like as a final product. To me colour is a minor issue unless the product is trying to win a competition. While I medicate in all possible ways my preferred option is to dab rosin and for that I use a press, I believe it makes a better product for dabbing than ethanol or any other method for that matter. After pressing the rosin chips get shredded and go into ethanol to extract any remaining goodness. I would be interested in any of your experiences with longer term ethanol washes. I won’t be surprised if you find you can soak for longer times and still get acceptable results, most certainly if you used a percolator in a freezer. I have not tried it but I would not be surprised to find that a high yield with little colour could be achieved by using a herbal percolator that is placed in a freezer and has dry ice added to the solvent reservoir then run it over a couple of days. The next time I make dry ice I will give this a go.

Water curing has been around for a very long time and is well known to people intimately familiar with cannabis processing. Having said that I don’t don’t know a singly producer that uses the method. I get that you are a fan of it, and I live by the idea of different strokes for different folks, but to me and almost every professional I know its not really even a process that would be considered. I forgot to mention about your earlier comment about leaving the wash in the sun. While yes it does change the color of the the chlorophyll, it doesn’t get rid of it, it is still there just in a different color. Lastly, you point on rosin. Comparing rosin to anything else is often done in an unequal way. All other extraction methods like CO2, butane, and ethanol are winterized to remove the fats and lipids to make a cleaner smokable product, but rosin does not do this. The allowance of leaving the waxes and lipids, which go strait into your lungs and can cause some serious problems, in rosin is what gives the extra flavor and aroma while hampering it’s potency. So yes, would agree with you that rosin tastes great and smells amazing, but if you are smoking a lot of it I would suggest winterizing it and then you will find it pretty much the same as ethanol and then also as potent as a solid ethanol extraction. As for time, the temp and time combination depends a great deal on the shape of the material being used. For the freezer I have stretched it out to many hours, and dry ice for over 48-hours. The yield pick up seems to top out in the freezer after about 30-40 minutes and 1-2 hours in dry ice

hi, would like to know what you think of these funnel filters that are called evonik membrane filters sold by sterlitech.com? I see other companys have something the same, they are suppose to remove plant color. thanks

I’m not sure, would love more info if you have it

according to this company evonik corp. who make this product and sale it on sterlitech.com, states that these filters (organic solvent nanofiltration osn, duramem membranes) simplify cannabis filtration by reducing the multistep processes of winterization, removing impurities and color removal (i.e. chlorophyll) while preserving up to 90% of thc & cbd. duramem membranes are stable in organic solvents such as ethanol and other alcohols and their tight pore structure (i.e. 200-900 daltons) make them ideal solution for simplifying filtration process and removing color. I sent them a text to get more info and order a 50 dollar sample pack of 10 they are pricey. thanks

Thank you for bringing this up, I’m going to order some to try as well! Thanks again!

so I just ordered a sample pack, PES membrane and .45um, .1um, and .03um she said that the PES membrane would be fine with alcohol and have better flow, also this well be a test on how well my vac can pull the extract thru the filter, she said that the .001um needs like 250psi to push extract thru the filter, but she said that the .03um should clean it up nicely. let you know how it works when I get them. thanks

Hey Chip! How did those filters work out for you?

Have you ever heard about or tried Magnesium Silicate (MagSil) to clean extracts?

There are a lot of silicate mixtures on the market for filtration, but I’m not as familiar with the individual components as I should probably be. Do you have something in mind?

Hey guys! I seen someone mention brita filters.

Would this be an alternative to using the AC / DE filtering process?

I have a new brita filter that’s been drying out for a few weeks that I was planning on sending my wash down through. I was considering sending the ethanol down through it first before the wash so it has “moisture” in the filter before the wash also.

Does / has anyone done this and are there any drawbacks to this method like loss of yield or anything else for that matter?

Thanks! Stay Safe! 🙂

I just tried this and the liquid is coming out clear does that mean the earth and carbon and absorbing all the THC as well?

It means you went too aggressive and may have scrubbed everything out. The only way to know is run it and see if there is any oil in there

How can I filter it less aggressively? Thank you! Was it too much charcoal?

Additionally what kind of filters are you using? With the earth in the filter it drips slowly and takes like 2 hours or more to do 1L while you took 5 min for 300ml. Is it my cheap pump or just too thick a filter paper?

Maybe less carbon and/or less time. Use less DE or larger funnels

As always, thanks for your work, saving us all time snd money.

A friend gifted me about 10g of FECO, which I appreciated, but edibles have no effect on me, so I thought about this article. Although after breaking it down in ethanol, running it thru a coffee filter (that was gross), then a fast and then a slow filter, it was still green edging on black but translucent. I was really surprised on that first pass thru the unbleached coffee filter, how many solids, lipids and fats there were. I should have run it thru a screen first, it was that bad.

After looking at what you started with and what I had, I decided I would most likely have to strip everything out to get it anywhere near a normal color. So I’m going to winterized the heck out of it and run it. I’ve smoked and dabbed worse looking stuff. At least I know the crap is out of there.

Your filter isn’t getting a good seal.

Set your filter paper in the funnel then start the vacuum.

Take a pippet, suck up some Ethanol then sprinkle the Ethanol onto the filter paper til it is properly seated & sealed into the Buchner.

I have been using britta filters for over 10 years, I dont notice any thc loss whatsoever and have made the same comparisons filtered vs unfiltered, the britta filter can be stored in a container of the same alcohol you use and can run a good 8-10 oz thru it, I make half oz batches at a time and evap with a fan, and will filter longer if you pre filter the mix of sediment with 1 brown unbleached coffee filter, run thru the britta, then use 5 to filter the end product, and get the pper filters wet with plain alcohol before filtering, it allows the slurrey to pass thru and not be absorbed by dry filters….results are amazing

Cool. How do you treat the filters beforehand? Any chance you want to hop in the user group and post some photos of the process and results?

hey so question about the D.E does it alter flavour as well? ive done just straight charcoal before with alot of coffee filters and micro mesh, just looking into different recipes for making it. i kmow using charcoal strips alot of flavor im just curious if that D.E leaves a taste

DE leaves no taste, assuming good filtering. Carbon won’t strip much clean extract flavor. It will strip undesirable swampy flavor thought.

Thanks for the info….can you send a link for the exact filters?

Hop in the user group and post the question, it’s easier to answer there.

Thanks for this – but note that your comment about the ST not being a powerful enough vacuum is false as long as a vacuum IS formed (which I assume it was). You can’t get a more powerful vacuum than a vacuum – IOW, if a vacuum exists in that bottle no matter how strong the pump would be it won’t go any faster. So the ST IS fine for this use.

I also wonder this – if the DE is that fine (as fine as flour) why DOES it get stopped by the 3 micron filter? Wouldn’t some (most?) of it just come through? If it’s dissolved that thoroughly in the ethanol you might not be able to tell (food grade DE is harmless, of course, but I doubt you want to consume too much of it).

To your first point, you are incorrect in your reasoning. All pumps have an ultimate vacuum level. Some are weaker some are stronger, it depends on the type of pump. The ST does not have very strong pumps and it is programmed to cut out at a certain vacuum level to facilitate boiling and evaporation for ethanol recovery. It is not programmed to go to it’s full vacuum potential. I know this because I am one of the two people behind the design, programming and product development. Yes it has vacuum, but relatively speaking it is not as strong as others.

To your second point. No. If it did that would have been included in the article.