By Troy Ivan

ibc@ichibancrafter.com

QUICK WASH ETHANOL (QWET) EXTRACTION

A clean and safe cannabis extraction process that can be performed at home is called “Quick Wash Ethanol,” shortened to QWET. It involves freezing cannabis and ethanol before combining them to soak the cannabis and “wash”(a verb) the cannabinoids and terpenes from the plant material. Once the combination of ethanol and cannabis has soaked, it is strained to separate the plant matter from the resulting ethanol solution, also called the “wash” (a noun). The wash contains all the components harvested from the cannabis and will later make up the final concentrate once the ethanol has been removed by forced evaporation. The best wash technique will create a concentrate with the maximum amount of cannabinoids and terpenes but the minimum amount of undesirable components like wax, lipids, and chlorophyll.

First, I wrote a blog post, “Super-Cooled QWET Wash for Cannabis Extraction Using Dry Ice,” explaining the process when I first experimented with very low temps with good success. As soon as that post was finished, I wanted to revisit the dry ice exercise to find out how far the wash process could be pushed and how it compared to simply using the freezer. So, here we are with the follow-up post and the epic Battle of the Wash: Dry Ice vs. Freezer!

WHY FREEZE?

There are many methods of infusion and extraction, all with distinct advantages and disadvantages. QWET, using high-proof food-grade ethanol (95%) as a solvent, has the advantage of high efficiency in collecting cannabinoids and terpenes. Unfortunately, that high efficiency of collection also extends to aggressively collecting undesirable water-based components like fats, lipids, and chlorophyll, ethanol’s only disadvantage. Fats, lipids, and chlorophyll can be acceptable when making oil for edibles or Full Extract Cannabis Oil (FECO) but undesirable for high-quality concentrates intended for smoking. To craft a concentrate free from undesirable components, they must be neutralized with freezing temperatures during the wash. When the plant material is frozen, and the ethanol temperature is below freezing, the polar attraction of the ethanol and undesirables in the plant matter cannot latch onto each other. The undesirables then stay with the plant matter when it’s strained away, leaving only terpenes and cannabinoids in the wash. The well-filtered wash should be a light golden color with no green.

MATERIAL?

I planned to use high-quality indoor dried buds for this battle to achieve high yields. Unfortunately, the material I got was crusty and not great quality. Using lower-quality buds may have actually been a blessing in disguise. I set the bar low for expected yields in using lower-quality buds, knowing high-quality dank will surpass it.

The goal in preparing the buds was to break them up by hand as much as possible, with the least amount of damage possible, to allow ethanol to flow freely over all surfaces. Ripping, tearing, cutting, and trimming plant material causes cell wall damage and will enable undesirables to flow unimpeded into the wash, contaminating and turning it green.

PROCESS

Pitting dry ice against the freezer required numerous runs of different durations to collect enough data points for meaningful comparison. I decided to do 3 runs in the freezer and 3 on dry ice. The washes would be 5, 10, and 15 minutes long for the freezer compared to 15, 20, and 30 minutes on dry ice. Each run used ½ oz of cannabis. After breaking up the buds and removing stems and seeds, there were 6 samples containing 13 g each. 3 bags went into the freezer for 24 hours, and the other 3 into a cooler with dry ice for 2 hours. The ethanol was also portioned between the freezer for 24 hours and the cooler with dry ice until it reached -40° F.

Once the materials were adequately cooled and frozen, it was time to make the wash. For each bag of frozen cannabis, enough chilled ethanol was poured to allow unrestricted movement of the material in the solution. Then, the bags were retired to the freezer or the dry ice cooler to soak for the predetermined period. The 5-minute washes were lightly agitated every 1 minute, and the longer washes every few minutes. When the time was up, the plant material was quickly strained away using 2 wire mesh coffee filters and then more finely filtered using a Buchner funnel. Once crystal clear, the samples went into a mason jar.

The concentrate was created at low temps under vacuum, around 100° F, and the ethanol was recovered for reuse with my DIY vacuum still system. The oil was lined up on silicone mats in order of extraction duration and grouped together with the freezer and dry ice samples separated. Finally, the oil was placed in a vacuum oven for post-process purging to make the final product into shatter and ready for comparison.

FREEZER OUTCOMES

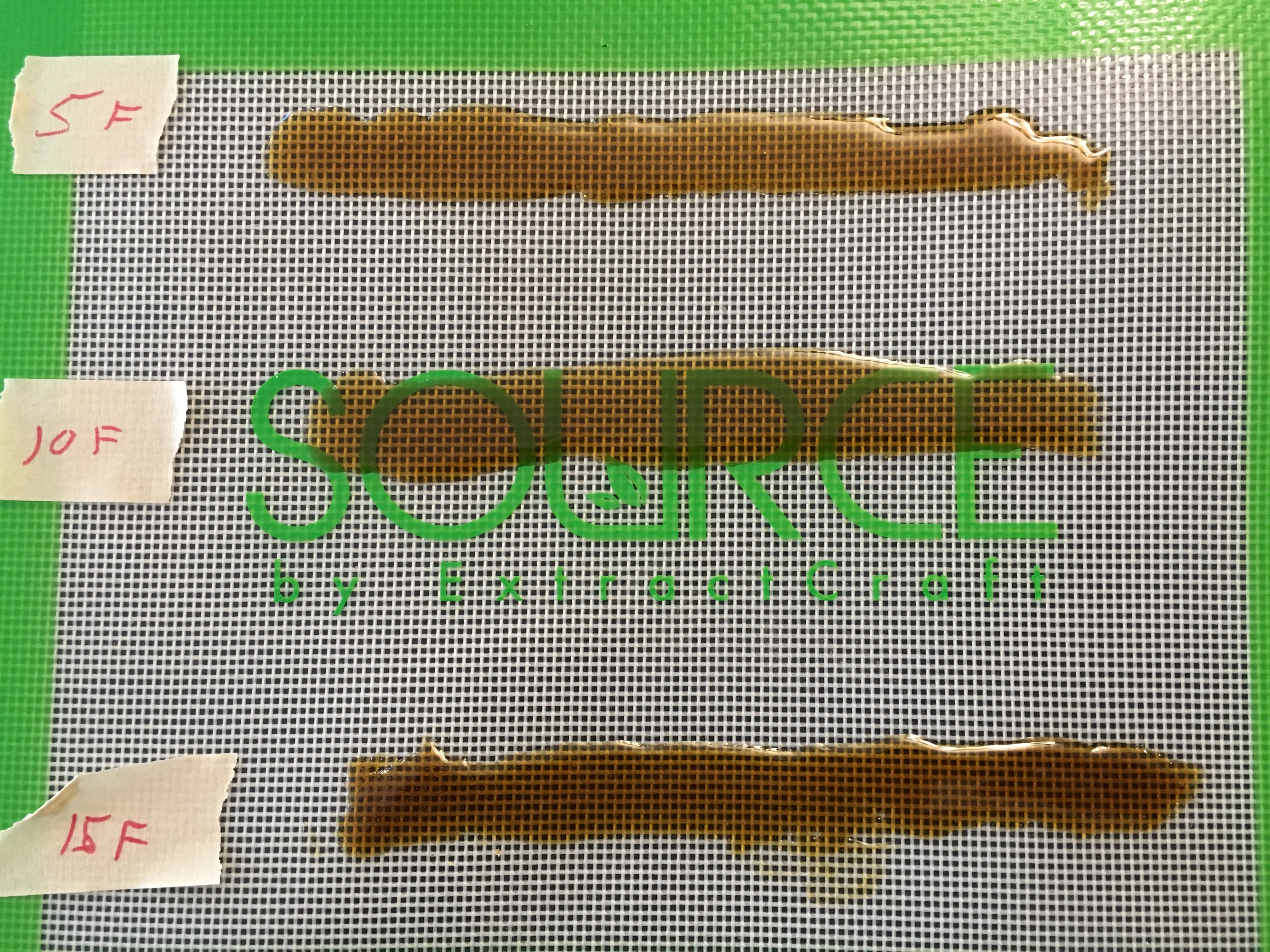

My expectation for the freezer washes was that as the soak time lengthened, I would see more and more green, with the 5-minute wash looking good and the 15-minute wash looking glaringly green. I was shocked and pleased to see the 15-minute wash come out nearly the same color as the 5-minute wash. There was only a slight difference between the 5 and 15-min while virtually no difference between the 10 and 15-min wash.

Once the final product was finished purging in the vacuum oven, it was apparent that the color of the shortest wash was only slightly lighter than the longest, but not by much. The final products were relatively consistent in color for all three samples, with the shortest wash showing only a marginal advantage with lighter color. The yields of the three washes from shortest to longest were 12.5%, 15%, and 15%.

DRY ICE OUTCOMES

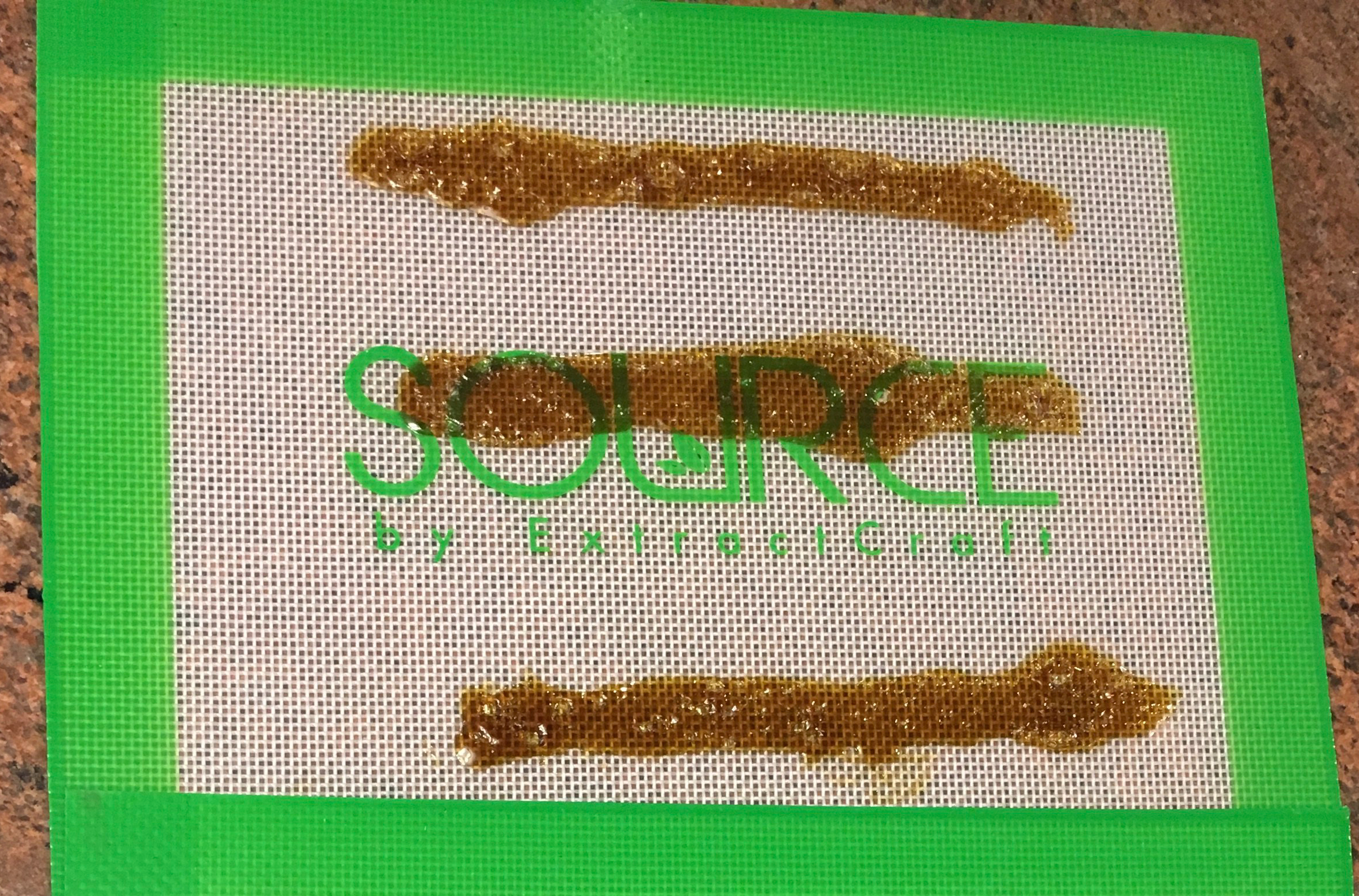

The shortest dry ice wash was 15-min, so I could directly compare a freezer and dry ice run of the same duration, followed by the 20 and 30-min washes. Again, by the time I got to the 30-minute wash, I was expecting to see obvious signs of green in the wash, but again, I was happily surprised to see almost no difference in color between the shortest and longest soaks.

All three final purged products came out very similar, with the shortest soak again showing only a marginal advantage in quality while the 30-minute soak still looked terrific. The yields from shortest to longest were 11.5%, 14%, 15.5%

Emboldened by the beauty of the 30-minute wash success, I was determined to find the limit and see where the undesirables would finally make their way into my wash and contaminate it with the green leak. I decided to perform a 1-hour dry ice wash in the same manner as the others. Again, a beautiful wash resulted, and the final product looked nearly identical to the 30-minute wash and yielded 16%. I was shocked again.

CONCLUSIONS AND CONSIDERATIONS

The shorter washes in each group were clearer than the longer ones, which is commonly expected. The unexpected was the narrow margin of clarity and color quality of the finished concentrates between each group’s shortest and longest washes.

I believe three factors made the very clean, long washes possible. First, while broken up thoroughly by hand, the material suffered only minor cell wall disruption, keeping the undesirables well contained. Second, through the entire wash cycle of each run, everything was kept well chilled and not allowed the chance to warm or vary in temperature. Third, the alcohol and plant material was separated with great expediency and never squeezed nor pressed.

In general, the yields of both groups increased with longer soak times, as expected. The 10 and 15-minute washes from the freezer were identical, both 1.96 grams. I think the 15-minute wash would have been a bit more if I had been more disciplined and consistent with the amount of alcohol used with every wash. It is apparent in the photos that the 15-minute freezer wash was 2 fl oz short of the other samples. I believe this reduced the final yield of that wash to some extent, but I don’t know how much. The dry ice samples showed an increase in yield to the 1-hour mark but increased at a slower rate between the 30-minute and 1-hour washes. I’m convinced the yields in this experiment were low due to the quality of bud used and can be improved with higher quality buds.

The stark difference between the freezer and dry ice runs clearly demonstrated that the lower temperature of the dry ice QWET immobilizes undesirables and increases color quality. I think using the dry ice performs two processes at the same time. Typically, QWET is done in the freezer, and then, to clean up further, the wash can be put back in the freezer to winterize. Using dry ice temperatures appears to perform both of these tasks simultaneously.

I would encourage those who try the freezer and the dry ice temps and times to use small quantities and explore which method and soak time suits their preferences best. This craft has no right or wrong; it only makes you happy, and your friends pass out. Whatever you choose, crafting with cold QWET will help you make FIRE with ease and win bragging rights!

IMPORTANT NOTE: I used ExtractCraft mats in this post but I do not recommend their equipment.

STAY LIFTED MY FRIENDS !!!

CHECKOUT THE ICHIBAN’S EXTRACTION LOUNGE GROUP ON FACEBOOK

In my own experiment, I found that not only was the color brighter doing the dry ice method, it had more flavor from terpenes. Dry ice imho, is superior to freezer method. Thank you for your excellent review

Excellent recap of total process with variables. Thank you!

Great article, keep them coming! You mention a vacuum oven. Is this only for make dabs? Or does it have other uses? Can you recommend a product that works for this process.

The vacuum oven, also known as a ‘drying oven’ is a standard piece of lab equipment used for de-gasing. For concentrates it’s used to remove residual contamination like butane, water, and ethanol. They are quite expensive and the pumps you need to run them are quite expensive as well. If you are just doing small batches for fun a simple single stage 3 CFM pump and 1.5g tank with a controlled heater is fine. You can find a package deal on Amazon usually with all of that together for $200-$300. The most common brand used is Best Value Vac

Can you vape it (qwet) without this final purge to become shatter?

Yes. Most vape juice contains a lot more ethanol

Hi, could you supply alink to the pump and heater you mentioned. Thank you for these articles, super informative.

I don’t have a link or promote any vac brands. If you google vacuum chambers, probably 1g or 1.5g and a 3cfm pump with a heat pad you should find some options

I was hoping for just this article! Great job, and Thank You!!!!!!!!!!!!!!!!

Thank you. Please share!

How much dry ice were you using for this experiment?

Had a couple pounds in a small cooler

Wow, I was thingking on doing the same data collection experiment once I got my Source in! Cheers for sharing the love!

Currently testing the process with room temp 192 proof 10min soak (I distill my own EtOH) on some wild sage for my 1st run just to test it out.

QUESTION: One can get down to nearly -80F with dry ice IN the EtOH (I have done so with a cold trap); so I was thinking about doing a 1hr QWET soak with dry ice in the EtOH. Wondering if -40F degrees more will make a difference (decrease the polar pickup of undiziribles) with cannabis?

Around -40 the “polar pickup” grinds almost to a halt. In this post I stopped at a 1-hour test but I think it could actually go on almost indefinitely. The colder it is the slower the pick up of the desirable as well. If you set two jars next to each other, like with orange peel or something, and do one with frozen ethanol and one with room temp ethanol you can visually see the difference in the speed of pickup. It is drastic.

Wonderful experiment! After all is said and done…. what do you end up doing most often…. did you find after reflecting more that dry ice really is worth it? Seems like the dry ice is interesting and useful but the cost might be an issue if you produce often? Perhaps one should do all their bud runs and save all trim – then run all trim in a narrow time period to save on dry ice. Also – have you ever had samples tested to see the differences that wash time and method on cannabinoid %s? I know we can extrapolate on relative differences based on color but would be interested what your 15% yield means in terms of % THC…. is that oil/shatter 50% THC or 80% THC. Such great work!

Hi, thank you for your kind words. I use my stand alone freezer mostly. Dry ice takes a little more preparation and the majority of my exercises are testing and experimenting so I’m normally not aiming for absolute perfection more than to gain more knowledge about the process. Having said that, almost everything I make comes out awesome using either the freezer or dry ice. You ask, “is dry ice worth it”. I think I explain that pretty well in the article and what I said there is exactly what I still think is true. Dry ice where I am is only about $1.60/lb so I haven’t been real thoughtful about maximizing the use of it, but for somewhere that its not available the efficiency with its use would be important, I just haven’t put much thought into it.

In Colorado there are very restrictive regulations on lab testing for unlicensed citizens, meaning I don’t have access to testing reliable testing facilities. The only tests that I have been able to get done have been in the mid 80’s and I don’t think there will be much difference between the dry ice and freezer, though just by the difference in color with the same material you would have to assume the dry ice would perform better. Hopefully, I answered your question satisfactorily, and thank you again for reaching out

How do you feel the return difference is from Ethanol to Butane?

With the quality I see here, I almost want to work towards using a less volatile solvent (Ethanol) than Butane, exe. What are your thoughts?

Oh man, I have seen some killer fights start like this, its a sensitive subject for many people, so I’d like to first say I am a firm believer in to each his own and everyone has their own path. For me its ethanol because I feel it is safer, cleaner, and less hassle. ‘Safer’ I think need no explination. ‘Cleaner’ as well I think is obvious especially as the ethanol I use is food grade. ‘Less hassle’ is debatable actually. I see butane as more of a hassle because blasting is pretty messy and dealing with the fumes can be problematic, but getting a good result is not so difficult. On the other hand, some people may say dealing with ethanol is more of a hassle because getting a good result takes more attention and can be unforgiving if not done properly. There are many other benefits of ethanol but this answer will get too long and I am currently working on a blog post to that end anyway.

Now for the yield question. This one is tricky, but by your question I am assuming you are quite familiar with BHO extraction. People report 20% and over for BHO, and I would say that is probably high, especially after dewaxing/winterizing. Ethanol is really dependent on exactly 3 things. 1) quality of starting material (same as bho) 2) quality of process 3) what you are making 4) how many washes you are doing. Obviously, quality material gives higher yields. The quality of the person executing the process is very important because if they are too fast, efficiency will suffer along with yield, or yield will be high because they left it go too long and picked up too many undesirables. What you are making impacts yield because if you are making a clean smoke then your yield will be lower than if you are making oil for edibles or FECO. Now here is where ethanol shines, you can do more than one wash. You can do a single wash to make clean smoke and pull 15%-20% then do a deep-long wash to make some FECO and grab another 10-15%. So the range for that entire spectrum is something like 7%-30%. Hopefully that makes sense?

Rad Info! Thanks

Your doing a great job for this plant! Keep it up ‘Crafter

Thank for the recognition brother, it is very much appreciated.

Thank you for sharing this information. After having a real challenge removing the chlorophyll, lipids and waxes from an ethanol extraction made by a MB machine, someone was kind enough to share this article with me.

I’m using this method solely for the purpose of making FECO to use in edibles and suppositories to treat intestinal disease. If my goal is to make FECO, not something to dab or vape, how would you recommend I wash it differently to maximize yield, without picking up excessive chlorophyll, lipids or waxes, which might be causing irritation and inflammation in my intestines?

Also, do you think a 2.5 micron, 94sec/100mL, grade 5 filter be too slow for this application?

Thanks again!

Mark, yes the MB pulverizes everything and is not designed for the cannabis plant. I would suggest reading my posts on making RSO and FECO as well as my QWET posts, all of the information is provided there (www.extractcrafter.com). I use both med and slow flow which are 12 micron and 3 micron. 2.5 micron is fine if you are doing a proper extraction, but if you are using the MB then you will have problems as the mud will just clog it up.

Apologize for the double post. I didn’t think the first one made it through, so I logged on and tried to retype from memory. I no longer use the MB machine. Hopefully, my second reply was worded better. Thank you

ah bummer, I just saw the “apologize for the double post” so I deleted it without reading, I assumed it was exactly the same. Was there anything important I missed?

I think the terminology was my problem. I was making my own FECO; but, after feeling like the chlorophyll was causing problems, I wanted to avoid the impurities inherent to FECO, which probably means I need a different end product at that point.

If I used more agitation or a warmer solvent, I could pull more out of the material, but I would gain the impurities with the increased yield. If that’s the case and I wanted a very high quality oil for edibles and suppositories, without chlorophyll, etc., would I follow the dry-ice cold ethanol extraction and just do a 2nd cold ethanol wash and combine it (post filter) with the first wash to maximize yield, as there wouldn’t be any need to separate the washes for my purposes?

For your purposes dry ice is probably overkill. I might do like a 1-hour freezer wash with agitation every 10 minutes and see what you think of that and go from there. Then do a room temp 2nd wash to make oil for cooking or topicals or whatever?

Thanks for sharing, super helpful info. I was wondering if you had tried maxing this out yet as previously mentioned? Soaking for 1 hr, 2 hrs, 3 hrs, etc… while maintaining -40 temps and seeing where the yield ceases to increase.

Thanks again,

Josh

Hi. I have not personally had time to go back to this yet. However, I have heard other followers have successfully left in overnight. Unfortunately, it’s not possible to compare those yields to mine because there are too many variables.

HI there, great article, i’ve been doing the dry ice extraction and evaporating the alcohol with a heating and stirring plate, but every time i get this amber transparent thick oil, never the solid yellow shatter, is this because of the temps i need to evaporate at normal Atm presure? how do you get the ethanol to reduce into that piece in the center of the extractcraft source paper?

I would guess it’s a combination of too much agitation and the heat

Really great article,

I have been looking at the methods of reducing chlorophyll and strong taste of oral extracts and gummies with full plant benefits. You put clarity into how cold! Freezer will get me started. Need to save my limited resources so I may obtain the turbo extractcrafter! Folks I know growing for themselve home thc and indy hemp are fine with rice cookers evap etoh into the air!

I am looking to extract industrial hemp as co now allows, and would like to create edible oil for gummies, and dropper bottle with MCT oil, and topical salves. I have never thought of smoking the extract.

I come from a nutritional herbal point of view and stopped smoking 30 years ago because it was not beneficial for me and thc to dance together, recent thc edibles experiences suggest still not in my best interest.

So I love cbd rich hemp products, sleep better, a bit of a relaxing effect…

I really resonate with the freezer EtOH method as I live in central co mountains, and want a good cold extract at 0 F and seems like lower temp ethanol reclamation with Exactcrafter will save terpenes and offer a more palatable cbd edible experience.

Again, thanks for your diligent article!

Thank you for the kind words! Best of luck with your CBD, terpenes make all the difference in the world.

Have you tried this QWET freezer or dry ice with kief extracted by the dry ice sieve method? Using the dry ice sieve technique you can produce high quality kief with little green plant from low quality trim.

Hi, I have not gotten around to it but I know people that do it with great success. The yield suffers a little but quality increases a lot.

Do you have any additional pointers for people who might attempt with Leif as I plan to?

Leif?

Considering myself scientifically minded, this is EXCELLENT! Love your process and the way you iterated. Have always just used/grown flower and was recently introduced to OpenVape on a visit to CO. My goal is to use my excess flower and trim to start making my own ejuice for that pen. What would you suggest at the most efficient way to achieve this? My thought was to make QWET then thin with MCT oil. Would you suggest a better method? And do you have a “recipe” for the QWET method (or if you think another is optimal) with budget in mind? Just hoping to avoid having to buy “theSource”, vacuum oven, etc unless they are highly suggested. All for personal use only, your feedback is greatly appreciated!

Hi David, thank you for the kind words. All you need to do what you are talking about is 1) The Source Turbo 2) Read my DIY CJuice blog post (https://extractcrafter.com/2016/08/04/diy-cjuice-ejuice-with-a-cannabis-twist/). Its pretty easy, absolutely no need for a vac oven to make carts.

Do you do multiple washes or just one? I know most people do at least 2, but they also only wash for 3 minutes or so. Obviously, yours are up to 15 minutes in the freezer and even longer with dry ice.

I personally would only do 2-washes. You might be able to get a little out of a third wash but I’m not that diligent, but if I had more time and it was necessary to really squeeze my budget I would consider it.

Makes sense to me. Thanks for answering and keep up the good work!

Can you direct me to info on how to do multiple washes? Is this process just for cannabis as I’m looking to use for hops? TY

Hops I would most likely wash efficiently the first time and wouldn’t be much value left. I’ve mostly used pellets so the collection was quite fast and easy

Can you please explain “multiple washes” for me. Are you saying new material is being washed in the solution to increase its potency? Sorry, I’m just not clear on this step.

It just means running the same material more than one time to make sure none of the good stuff is left behind. The first wash will only pick up around 70% or so of the cannabinoids available if you are doing a frozen or quick wash, so doing a second wash of the same material to gather what was left behind makes great economic sense. On the other hand, if you are doing an aggressive and long soak you are probably getting everything that’s available so a second wash is probably not necessary.

Another great post. What speed filters are you using with the Buchner filter? I’ve got slow, medium, and fast. Is it worthwhile to run through a couple or all the filters? I’ll be using the Source’s vacumn hookup through the filters. Does the vacumn oven make that much of a difference? I thought I had everything ready to go but hadn’t seen the oven before.

I use slow filters which are about 6 micron, medium flow would probably work, but I always feel happier with the results of the slow filters

Thanks for the info about filter size. I want it to come out as clean as possible, so I don’t mind waiting if it’s worth it.

Should be interesting. Using various citrus and later in the year, cherries to produce our own bitters, syrups, and other ingredients needed for craft cocktails.

The vacuum oven is super useful and convenient but it’s very expensive and not necessary

What kind of filter are you using? Is their any carbon?

I’m only using paper filters. I should step up my game to some carbon or silica but I just haven’t had the time to get there yet…….

May I ask your process for filtering with carbon?

I typically don’t carbon polish. I take most care in the wash process and all I do is for personal consumption and testing. If I were larger scale and producing professionally I might do, but then again I might not unless I was polishing crude to improve distillate clarity output. I think Summit Research has some good input and silica compounds if you are interested in advanced filtering mediums.

Thanks so much for your time and effort to put this report together! Any comments about the moisture level of the plant material? I would imagine that drier is better, but wouldn’t want it at the crumble stage…

It’s my pleasure and I hope it helped. Yes, the dryer the better, assuming you are talking about material that has been properly harvested and stored. I have seen 15% suggest and the minimum moisture content, but I don’t know exactly why that number was accepted to be the imaginary cutoff.

I plan to use this frozen qwet technique real soon. I hope to use the ethanol to wash multiple batches before boiling off the solvent. Have you tried that? Do you have an idea of the solubility limit of thx in ethanol? Will save me some evaporation time.

What is the temp and pressure you are using for the vac oven? How do you know when your oil is clean?

My oil is always clean because I only use food grade ethanol so I’m not worried about some residuals because it holds no adverse health effects for me in those minute amounts. I use full vac around 90F most the time. Lately, I have also been messing with 112F at full vac with the pump running for 24hrs which has been putting out some good results. I also sometimes work at 85F and leave under vac for a week or more. There are many ways to skin that cat, you just have to find the one you agree with the most.

You are brilliant! This is so fascinating. Thank you again for sharing your results with us.

Thank you

What was your typical yield variance between using dry flower and wet frozen? In regards to your yield from fresh frozen vs quality of end product, is it possible for a processor during tests to determine extraction yield upon which a wholesale producer is paid, to during the processing manipulate the yield downwards? If so could such low yield also result in actually increasing the final value of their end product?

Due to the mass of fresh material compared to dry your yield will be much less

After reading your articles, I ordered The Source. You have made it very clear that it’s well worth the money to create the best quality extractions. THANK YOU SO MUCH for your wonderful articles!!! You are generous, you write very clearly and your instructions are fantastic!!!

Thank you for your kind words. Happy Crafting!!

I absolutely love my source turbo. And I’ve only just started crafting with it. After doing my Pyrex dish on the glass top stove to evaporate and collect the oil .This machine has not only helped me produce the highest quality dabs I’ve had yet. But its a bed me money by allowing me to reclaim most my alcohol .And its safe and easy to use.xand so so so much cleaner than the old ways .

Now I’ve just got to start extending my wash times and get that down Better .But so far. Both times I’ve done 14 gram nugs washes with 200 proof organic grain alcohol that both have been in freezer for 48 hours be4 wash. And I yielded. A lil over 2 grams both times . and the quality is unreal .Tastes amazing. And I look forward to crafting many more batches .Thank you for such great info .I always learn A lot from every one of these posts.

That’s great to hear, thank you!!!

If you want to decarboxylate your oil to use as a sublingual you will boil off and lose some terpenes and flavonoids. Is it possible, once you have distilled off the ethanol, to distill off the terpenes and flavonoids that would be lost at temperatures up to 248°F before you decarboxylate the oil? Can you decarboxylate under vacuum and would that make a difference as to the loss of terpenes.

Decarbing under vac would lose more terps. It’s a complex problem that’s hard to conquer at home. The best you can do to save the terps is decarb in a container that you can also do the wash in. After decarb, don’t open and let cool, then either freeze for QWET or go straight wash.

Thank you. Expanding on your suggestion, if I decarbed my bud in a sealed vacuum food storage bag immersed in 248-250°F water using an induction cooktop with tight control of the temperature, then cooled and returned to my freezer, I could preserve the Terpenes and flaveroids for extraction with an 200 proof ethanol wash. This may help preserve taste and beneficial terpenes. Since I can boil off the ethanol at about 175°F Terpene loss should be minimal. Do I have this correct? Do you agree with the decarb temperature? And if so in a sealed container should I consider 30 minute or 60 Min decard time?

Not sure how I missed this (and quite a few others). Glitch with WordPress? If you are boiling off the ethanol in open air at 170F you will quite a bit of the good stuff and depending on how much you are doing and how long it takes it may negate the necessity to decarb prior

Question: Do you need to keep your buchner/erlenmeyers in the dry ice too? I tried your method and had good results, but was paranoid about the erlenmeyers breaking with the temps so I put them in the dry ice cooler too. I quickly ran out of room and it was a step that I’d prefer not perform.

You don’t need to put the filtering equipment on dry ice

Thank you. I made the mistake of filtering the ethanol liquid into a pyrex bowl which shattered instantly. I was hoping that Borosilicate glass wouldn’t shatter so thank you for the confirmation.

Pyrex shattered? Never seen that before, you sure it was actually pyrex? I normally use stamped stainless mixing bowls myself

You can throw a piece of dry ice ito the liquid while it is filtering it’ll keep it at low temp and assure all waxes stay solidified and don’t go thru the filter..

There is no need to do this. The dry ice can become somewhat violent and it provides no advantage. Running it through the Buchner will be fine by running normally and the liquid won’t warm that quickly if you are running the Buchner properly

I don’t have a buchner yet…, but my ethanol stayed very cold. Using a Thermopen, I observed that the solution was still below -40 even after sitting in the coffee filter for a few minutes dripping. It was so cold that when I put it into my distiller, the machine errored out due to the solution being too cold.

do yourself a favor and get a Buchner funnel setup, you will be happy you did.

Hi Sensei Ichiban. Im looking to get started right away winterizing raw crude. I may start from trim or flower but haven’t decided yet. But If Im using the Dry Ice Method you mentioned, can I apply the trim procedure you’ve mentioned to the raw crude procedure and still attain the same results? Please let me know, thank you very much.

Have you gone through my winterization post?

Is it OK to use the same vacuum pump that comes with a vacuum chamber with the buchner funnel? (1/4HP 3CFM). Or is it advisable to use a hand pump? Thanks so much!

the vacuum pump with the vac chamber will work well. You will want to review the recommended procedures and uses of the pump with solvents. My guess is it will recommend using a cold trap

I got a cheap hand pump on Amazon (a kit for doing brakes) for like $20. It does everything I need: vacuum filtration with a buchner/flask, and extraction of the recovered alcohol in my Source Turbo (with a liquid trap that came with the kit). This recovery allows me to keep adding solution to the Source without having to finish off the oil until all of my solution is ran.

Hi Dave S, what kind of cold trap came with you kit….what kit was it? Thanks!

Not a cold trap, just a liquid trap to use when the ethanol recovery collection chamber is full. That way I don’t have to disassemble the SourceTurbo every time I have boiled off enough ethanol to fill the collection chamber. This allows me to continuously add new solution to the boiling chamber.

I wouldn’t recommend adding new solution to the boiling chamber, it will increase the chance of bumping and increased splatter.

This is the kit.

https://www.amazon.com/dp/B00NP60URE?ref=ppx_pop_mob_ap_share

What would be the best filtering setup if I dont happen to have a berchner funnel handy?

1) strain all the plant material and separate with a good strainer 2) if you have a fine wire mesh coffee filter run it through to separate better 3) put wash in a jar and allow to set for 2hr-24hr and allow all particles to fall out and settle like sediment on the bottom of the jar. 4) Gently pour off the clear top 3/4 of the jar careful not to disturb the sediment 4) When you get to the point you cant avoid the sediment any longer run it through a stack of 3 unbleached coffee filters into a separate container from the top clean part of the wash. You may want to forgo pouring the thickest part of the sediment into the filtering, you won’t loose much 5) Decide to combine the separate washes or combine together. The top of the wash will certainly be clean, the last part may be less clean, you will have to observe and decide.

Thanks for the info. I left my material in the wash with the dry ice method for 8 hours. Got a nice golden liquid and no undesirables. Yield was about 18%

Perfect!

Wouldn’t it be a good idea to do a second cold wash? I feel like that would increase the yield for two reasons, while not decreasing the quality by much. When you do one wash, there’s a significant amount of solution left behind in the bud. If you do a second, you get the vast majority of the compounds you’re looking for out leaving a more dilute solution soaked in the bud. Also, I don’t know what the solubility of cannabinoids and terpenes are at freezer temps and below is, but it could be, depending on the volume, that you’re reaching the limits of solubility with only one wash. I’d be very interested to see how one 15 minute wash compares to a 7.5 minute wash followed by a second 7.5 minute wash. You could then purge the first and second separately to see the difference in yield and quality as well as compare the total yield to the 15 minute wash.

There are an infinite number of possibilities and efficiencies. I would suggest you run some of those test you have interest in and report back, that would be interesting.

I used a triple consecutive wash technique (at -25F super cooling freezer). Used 5 quart jars of trim/failed plants and three quart jars of Everclear. First alcohol jar was put in first trim jar and washed for 1 hour, then 1st alcohol jar was transferred to second trim jar (supplemented by additional alcohol because some alcohol stayed absorbed in the plant material). Second alcohol jar was then transferred to the first jar of trim and 1st and 2nd jars were washed for an hour again. Of course, all of this occurred in the freezer keeping everything at -25F. Each of the three jars of alcohol successively washed all 5 jars of trim. In the end I was able to recover 2.5 jars of solution. The Jars were quite dark gold. I extracted the oil using the Source Turbo (thanks for spreading the word about this device ICHIBANCRAFTER). Effectively this was 3 hours of extraction time and the oil is beautiful and potent.

Just my experience with this technique for anyone who is interested.

I recently watched online a very successful extraction using this method. 1 hour wash on dry ice with ethanol also chilled on dry ice (under -40 degrees). -Filter with buchner twice. Then a second wash for another hour with fresh chilled ethanol -filter, followed by a quick rinse. (Rinse was simply super chilled ethanol poured into the material, swirled once, then immediately filtered. ) Effectively a three rinse extraction. No chlorophyl was leached out. Nice golden color. The third rinse increased overall yield by 2% over the same method without the 3rd rinse. The only downside is that you need more ethanol. Combine all of the extractions together then distill, place in vac chamber for 12 hours @100degrees. Result was 15% yield with average material. 13% without the third rinse.

Can you tell us the type of freezer you used and the temp it reaches, Ichiban?

Normal standup freezer kept in the garage, gets to about -5F

I’m pretty new to this and tried a variation of the freezer method described here today. I’m hoping you can help me troubleshoot to figure out where I went wrong and what I can do from here. A friend gave me the trim from this year’s grow. It’s not very high quality, mostly larger leaves, but some tiny little buds and sugar leaves. I was hoping that what it lacked in quality it might make up for in quantity, because I had a lot. I decarbed in the oven, then filled a mason jar, filled with 150* alcohol pre-chilled in the freezer, shook for a minute, then put in the freezer for approx. 5 minutes, remove, strain, and repeat. I had enough to repeat this process about 5 or 6 times, using the same alcohol each time. At this point I ran through a coffee filter and evaporated in a double boiler until I got a very dark, very viscous and sticky oil. At this point I wanted to dilute into e-juice that I can vape. I tried both vegetable glycerine and commercially purchased CBD e-juice that includes VG and propylene glycol (1 g oil to 2 ml solvent in each case), and it wouldn’t dissolve into either. For both it mixed briefly when heated, then separated again. I know that I didn’t follow the recommended protocol exactly (more dilute alcohol, poor quality trim to start with, etc), but is there anything I can use this for? Any idea why it won’t dissolve? Any use for the unhomogenized oil/solvent mixtures? Recommendations for resources that can help me answer these questions myself? Any help is appreciated.

I think you might do well to read the “Good Shatter From Bad Trim” post on this site, it might shed some light. Its hard to say exactly without me having it in hand. First, the 150-proof is going to be a problem with residual water. Second, there may be too many undesirables (fats, lipids, wax, etc). Lastly, a double boiler is really going to ruin the quality of the oil, but probably shouldn’t effect separation.

VG doesn’t blend with cannabis…period. 150 proof alcohol is too diluted. You need at least 190 proof. Also, what temp did you evaporate the alcohol? If you didn’t finish it in a vacuum chamber that would also explain the runny consistency. As far as vape juice is concerned, try using a terpene liquefier at a much lower ratio. max 2:1 oil:terpeneliquefier. Add a couple of props of flavor terpenes for flavor if desired.

Also, you said you filtered the solution then used it again? That is counter productive if you were putting the same cannabis infused alcohol solution back onto fresh cannabis. Use fresh alcohol. You would also benefit from a good filtering process -invest in a buchner funnel, flask, filters (about $25-30 on ebay. ) You will have vastly improved results compared to simple coffee filters.

Don’t get discouraged. Each time to extract you will find ways to improve you results. Spending a little extra time and a few $ on some basic supplies will be very beneficial.

Question about vacuum chamber. Why does everyone seem to put their extract on a silicone pad? It is such a mess and from time to time the oil might run off the pad and make a mess. Why not just put your concentrate into the chamber in a glass beaker. When it’s finished degassing, there is no need to scrape off the pad because it’s already in a container. (Just make sure you know the tare weight of the container before you fill it.) I’m just going to add my terpenes and liquidizer to the finished extract in the beaker then go straight to cartridges. IMO it just makes sense because you’re losing product from extract sticking to everything. Thoughts?

Getting off a mat is very easy. Don’t ‘scrape’ that will make a mess. Fold in half, press together, put in freezer for 1 minute or so then peel one side off. Repeat folding and peeling until you have the shape you want. Don’t leave in freezer too long or it will throw little glass shards all over and make a big mess

Totally, that is what i do and working perfectly every time👍

I have 5 grams of keif and want to concentrate it, how many oz. of alcohol and how long to wash? thanks

Something like 10:1, kind of eyeball it. It better to use too much than too little. I would freeze both the alcohol and keif for 24 hours, then do a 10-min wash or so with good agitation

I wash my buds 10 minutes I was scared it would be to long for the keif. thanks

I just add the kief/hash/scissor hash into my broken up buds to increase overall yield. Seems to work just fine with my 2, 1 hour soaks at -50degrees F. I distill in full vacuum keeping the temps under 100degrees F though. (I did it also with a regulate heated distillation and it was fine too).

Hello Ichiban, thank you for the very informative articles many thanks! If one was wanting to have high yields and quality shatter made with the EtOH PRO and one had access to a lot of kief and trim to do dry ice QWET washes with what would be the best ratio of shake to kief to mix? Could a person wash kief by itself or is it better to mix with trim?

Kief by itself is fine. Still use a frozen qwet approach. At least 10:1 but with the EtOH PRO you have so much power you can use extra ethanol just to make sure the pickup is faster and more complete.

just washed my 5 grams of kief came out very dark is this to be expected? I decarbed it as I am going to make it into mickey-t mct oil tinctures so not to big a deal just wondering for future runs. thanks

Depends on many factors, decarb causes oxidation and affects color for sure. Did you freeze the QWET?

yeah for 24hrs in garage freezer its right at 3 degrees, washed 10 min. I kind of thought it would get dark your because of it being so fine, I did 8 grams of regular buds side by side and that came out very clean the outside freezer worked much better. thanks

Does anyone use any type of grinder/shredder/mill to process flower before the extraction process? I’ve read that if you grind it up, you will leech undesirables. Is that true at extremely low temps? It is rather time consuming to process flower that is solid as a rock by hand. Also, the volume of the hand picked/broken up flower is rather high so you need more ethanol to cover it. If it is shredded, you could use less ethanol to cover the material.

Some do. Just have to use cryo temps and know the material you’re using. I still take the time to do by hand usually though

I’m reading an awful lot on cannabis distillation. They say after an alcohol wash, take that used material and use it for distillation… how might you think that gets done?

Depends what they are talking about. Where are you seeing this?

Do you have test results or an estimate of the % purity of the final cannabis oil extraction using the dry ice QWET method? My steps are:

Decarb using Ardent Nova

Dry ice extraction using 95% 190 proof Everclear

Büchner filter to 4 micron dewaxing

Distill the Ethanol using ExtractCraft Source

usually in the 80s

First, tumbled in here and best most clear information on Ethanol distilling. Thank you!

Just curious, after all the filtering and distilling, what is the best ideas of what non-THC components remain?

terpenes, flavonoids, and stuff

I recently started using vacuum distillation to keep temps down. Works great and final product is wonderful but it takes a lot longer than my old countertop water distiller. Idea was that if I kept temps low, terpenes would not be lost. I was able to distill at around 100 degrees under vacuum yet the terpene profile was not much different than when I distilled at 180 degrees F . After going through experiment I read in many places that ethanol extraction will destroy many of the terpenes that I was hoping to capture in the first place. Ugh

So here is the question. What affect does distillation temperature have on color? My vacuum distilled extract was a very nice light color, but I also upgraded my filtration to sintered buchners using Celite 545. I think that better filtration produced the lighter more refined colors more so than the lower distillation temps. The reason I’m asking is that lower temp vacuum distillation takes A LOT longer than my countertop wine distiller. I’m thinking about distilling off a large portion of the ethanol in my countertop distiller before transferring for finishing in the vacuum distiller but not sure if the final product will be noticeably better. Seems like just more work and things to clean. Any ideas? Thanks for all the help and advice! Nice to finally be in a USA state where this is legal.

There is a lot to it and I probably don’t have to time to run through all the thermal dynamics, vacuum functions, and all the factors involved. The short of it is simply putting a pot under vacuum isn’t really efficient and the chances that you were really working at 100F is quite low. Why not just buy the equipment made for the process you are looking to use?

Because vacuum Distillation lab hardware was $120. 🙂 When I bump up the temp to 140 degrees, it flows really well but still, not as fast as at 180 with a larger non vacuum distiller. Honestly capacity is the issue with the Turbo. If you have 2 gallons to distill, that’s not an option. Etoh Pro looks nice. But I already have an aspirated chilled vacuum pump, heat source, distiller condenser (which gets chilled from the water in the vacuum pump.) Rotovap is the next step, but the results I get from the much cheaper options are very good.

Right, sounds like you have it all figured out. Good luck

Nope. Haven’t figured it all out. Just like to try all the options before I find the best one. Vacuum distillation is wonderful, but like I said it takes longer. That’s why I’m trying to figure out what affect distillation temp has on color of final product. I’ll report back my findings.

So after testing, yes, higher distillation temps result is slightly darker colors. Honestly, flavor profile is not much different if not the same. I have been itching to try the ETOH Pro to lower temps because of its larger capacity. Saw on Facebook on the manufacturers page that there was a sale. Unfortunately they were sold out before I got a chance.

If distillation temps didn’t make a huge difference in quality then everyone would use higher temps as it’s infinitely easier and faster

this article was straight knowledge!

Is it better to use dried flower/trim instead of fresh frozen in the qwet process. My fresh frozen trim has frozen water particles all over the material – would the frozen water cause a problem with the final oil product?

Thanks!

Ethanol extraction needs to have dry material. For the closest thing you can use a freeze dryer put fresh material to good use

ok I’m glad I asked! I don’t have a freeze dryer – I’m probably going to make bubble (ice water) hash with it now. Are there any issues with using the live resin bubble hash in an ethanol extraction?

Dude keep up the blog, it is awesome!

Bubble hash will work, just make sure it’s dry and use frozen QWET

I did a few comparison qwet washes last night….a 1st and 2nd wash on undecarb’d dried flower, and a 1st and 2nd wash on decarb’d flower. The undecarb’d came out light gold (1st wash) and light green (2nd wash). However, the decarb’d came out a richer/darker yellow/gold coulor, and the 2nd wash (which I left in the freezer for 8hrs and agitated more) came out yellow as well with a slight tinge of green. How has decarbing lessened the chlorophyll bleed into my qwet?

thanks for all the help!

You basically cooked the chlorophyll and reduced the moisture. Just look at the difference in color of material that is decarbed and some that’s not. You can see it in the cover photo of my decarb 101 post. It fades from material that is green and not decarbed to some decarb to fully decarbed, green to brown

that’s the conclusion that I came up with but I felt stupid telling you I thought I cooked the chlorophyll lol!

Dude, your awesome…thanks for helping me learn bro.

My pleasure, never feel stupid we are all out on the cutting edge learning what we can, stay lifted

Probably a stupid question, but if you decarb and then QWET… have you basically produced a tincture without the undesirables? Assuming that you wanted to make edibles that don’t involve fats (gummies, for eg) is this the best stage at which to stop, or is there an advantage to filtration and solvent extraction?

Its easier to work with the concentrate as it is easier to approximate dosage and consistent production

Thanks for the quick reply! I should have looked around the site more. Just after posting I saw your blog on “Cannabis cooking and edibles with the Source” which answered my question – that you remove the solvent to leave a known amount of extract, then add a known amount of carrier (which could be ethanol again) to ensure better dosage based on more accurate concentrations.

Hi. You provide truly awesome directions that allow folks new to the craft to understand the relevance of each step. Thank you for your time!

When do you decarb during the QWET process? Is that done coincidentally with the heat produced by the reclamation of the ethanol? What is the minimum temperature/time for decarbing? Can I decarb prior to the first wash? Do you know any (dis)advantages to decarbing in the oven v. in a mason jar in hottish water.

Appreciatively,

-Geoff

Thank you for the kind words. I would suggest reading my post on decarb for answers to the questions you have here. https://extractcrafter.com/2019/01/29/decarboxylation-decarb-101-basic-understanding-and-at-home-method-comparison/

Questions about a second wash. I assume you are using fresh Everclear for both washes. Do you put the Source material back in dry ice then process it? Do you mix the 2 washes or process them separately?

Totally depends on what you are trying to make and your balance of clean extract to efficiency. If you are going purely for efficiency and maximizing yield then you could mix the two washes. But then if you think about it, if your first wash was really clean, and the second isn’t usually so clean and you are going to mix them together, lowering the quality of the first wash, why not just do a longer and more aggressive first wash? It is always a balance of pickup efficiency against clean extraction. How you do it and weigh the importance can only be determined by you and what your end goals are.

Hi. I purchased the Source extractor and I don’t want to use the vacuum pump on the unit to suck the washed material through the Buchner funnel and filter. Can you recommend an appropriate pump for this? I’m not sure what specs (pressure, safety, quality) need to be meet. I heard that one should use an ethanol-safe pump. Not sure what that means.

Thanks for your thoughts!

-Geoff

Any 3cfm pump and a cold trap. I would just use the Source personally