By Troy Ivan

ibc@ichibancrafter.com

QUICK WASH ETHANOL (QWET) EXTRACTION

A clean and safe cannabis extraction process that can be performed at home is called “Quick Wash Ethanol,” shortened to QWET. It involves freezing cannabis and ethanol before combining them to soak the cannabis and “wash”(a verb) the cannabinoids and terpenes from the plant material. Once the combination of ethanol and cannabis has soaked, it is strained to separate the plant matter from the resulting ethanol solution, also called the “wash” (a noun). The wash contains all the components harvested from the cannabis and will later make up the final concentrate once the ethanol has been removed by forced evaporation. The best wash technique will create a concentrate with the maximum amount of cannabinoids and terpenes but the minimum amount of undesirable components like wax, lipids, and chlorophyll.

First, I wrote a blog post, “Super-Cooled QWET Wash for Cannabis Extraction Using Dry Ice,” explaining the process when I first experimented with very low temps with good success. As soon as that post was finished, I wanted to revisit the dry ice exercise to find out how far the wash process could be pushed and how it compared to simply using the freezer. So, here we are with the follow-up post and the epic Battle of the Wash: Dry Ice vs. Freezer!

WHY FREEZE?

There are many methods of infusion and extraction, all with distinct advantages and disadvantages. QWET, using high-proof food-grade ethanol (95%) as a solvent, has the advantage of high efficiency in collecting cannabinoids and terpenes. Unfortunately, that high efficiency of collection also extends to aggressively collecting undesirable water-based components like fats, lipids, and chlorophyll, ethanol’s only disadvantage. Fats, lipids, and chlorophyll can be acceptable when making oil for edibles or Full Extract Cannabis Oil (FECO) but undesirable for high-quality concentrates intended for smoking. To craft a concentrate free from undesirable components, they must be neutralized with freezing temperatures during the wash. When the plant material is frozen, and the ethanol temperature is below freezing, the polar attraction of the ethanol and undesirables in the plant matter cannot latch onto each other. The undesirables then stay with the plant matter when it’s strained away, leaving only terpenes and cannabinoids in the wash. The well-filtered wash should be a light golden color with no green.

MATERIAL?

I planned to use high-quality indoor dried buds for this battle to achieve high yields. Unfortunately, the material I got was crusty and not great quality. Using lower-quality buds may have actually been a blessing in disguise. I set the bar low for expected yields in using lower-quality buds, knowing high-quality dank will surpass it.

The goal in preparing the buds was to break them up by hand as much as possible, with the least amount of damage possible, to allow ethanol to flow freely over all surfaces. Ripping, tearing, cutting, and trimming plant material causes cell wall damage and will enable undesirables to flow unimpeded into the wash, contaminating and turning it green.

PROCESS

Pitting dry ice against the freezer required numerous runs of different durations to collect enough data points for meaningful comparison. I decided to do 3 runs in the freezer and 3 on dry ice. The washes would be 5, 10, and 15 minutes long for the freezer compared to 15, 20, and 30 minutes on dry ice. Each run used ½ oz of cannabis. After breaking up the buds and removing stems and seeds, there were 6 samples containing 13 g each. 3 bags went into the freezer for 24 hours, and the other 3 into a cooler with dry ice for 2 hours. The ethanol was also portioned between the freezer for 24 hours and the cooler with dry ice until it reached -40° F.

Once the materials were adequately cooled and frozen, it was time to make the wash. For each bag of frozen cannabis, enough chilled ethanol was poured to allow unrestricted movement of the material in the solution. Then, the bags were retired to the freezer or the dry ice cooler to soak for the predetermined period. The 5-minute washes were lightly agitated every 1 minute, and the longer washes every few minutes. When the time was up, the plant material was quickly strained away using 2 wire mesh coffee filters and then more finely filtered using a Buchner funnel. Once crystal clear, the samples went into a mason jar.

The concentrate was created at low temps under vacuum, around 100° F, and the ethanol was recovered for reuse with my DIY vacuum still system. The oil was lined up on silicone mats in order of extraction duration and grouped together with the freezer and dry ice samples separated. Finally, the oil was placed in a vacuum oven for post-process purging to make the final product into shatter and ready for comparison.

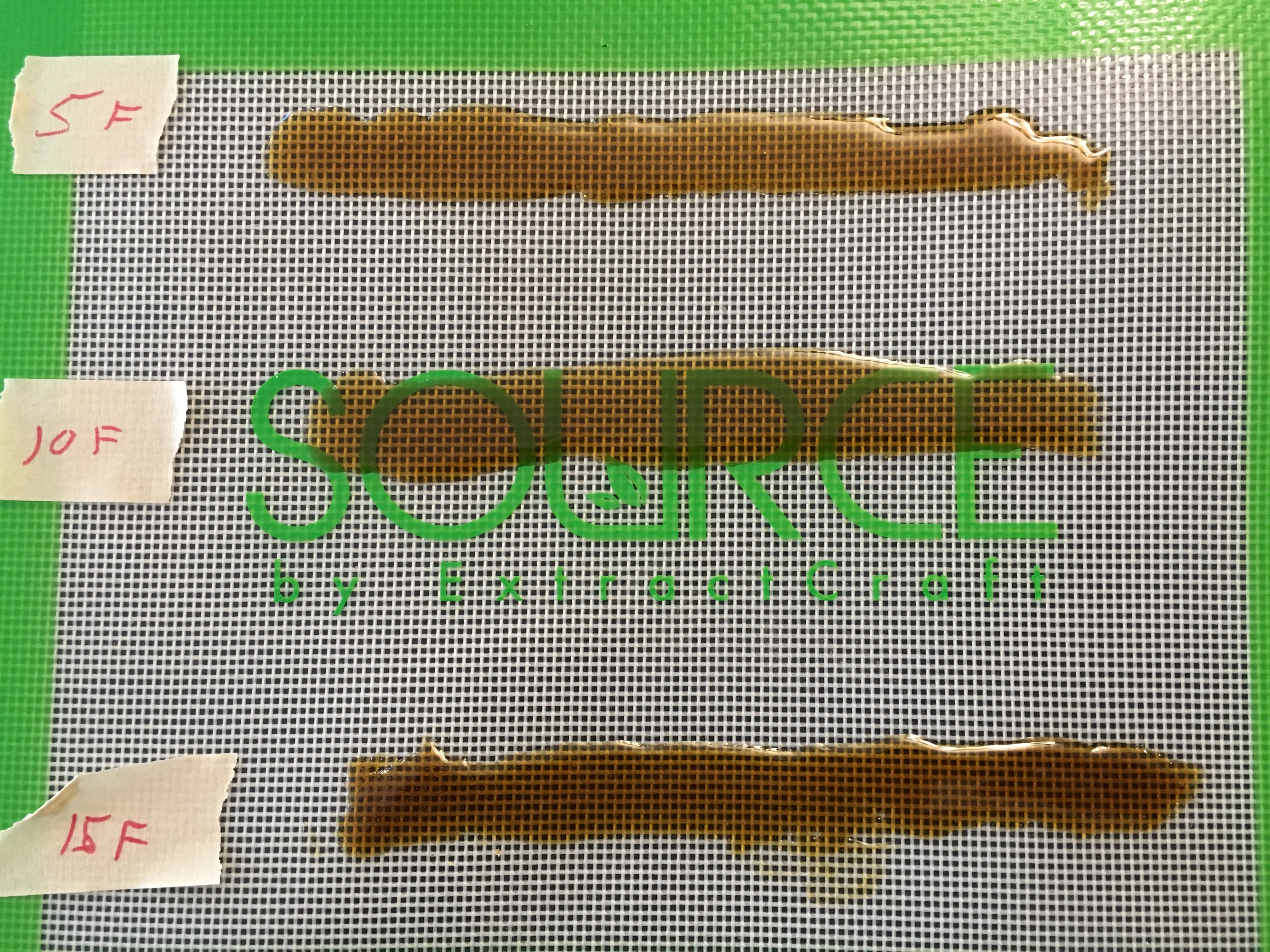

FREEZER OUTCOMES

My expectation for the freezer washes was that as the soak time lengthened, I would see more and more green, with the 5-minute wash looking good and the 15-minute wash looking glaringly green. I was shocked and pleased to see the 15-minute wash come out nearly the same color as the 5-minute wash. There was only a slight difference between the 5 and 15-min while virtually no difference between the 10 and 15-min wash.

Once the final product was finished purging in the vacuum oven, it was apparent that the color of the shortest wash was only slightly lighter than the longest, but not by much. The final products were relatively consistent in color for all three samples, with the shortest wash showing only a marginal advantage with lighter color. The yields of the three washes from shortest to longest were 12.5%, 15%, and 15%.

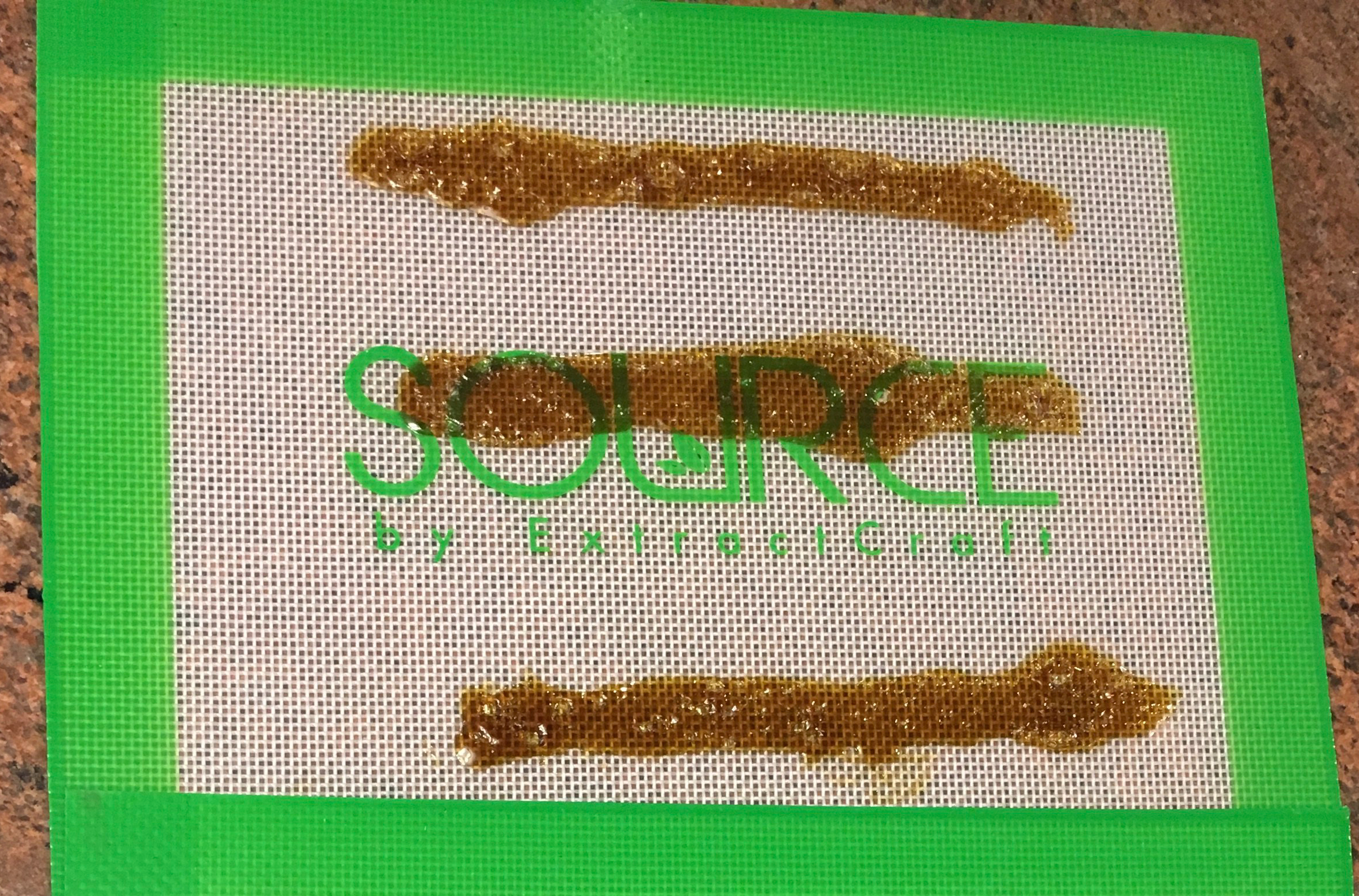

DRY ICE OUTCOMES

The shortest dry ice wash was 15-min, so I could directly compare a freezer and dry ice run of the same duration, followed by the 20 and 30-min washes. Again, by the time I got to the 30-minute wash, I was expecting to see obvious signs of green in the wash, but again, I was happily surprised to see almost no difference in color between the shortest and longest soaks.

All three final purged products came out very similar, with the shortest soak again showing only a marginal advantage in quality while the 30-minute soak still looked terrific. The yields from shortest to longest were 11.5%, 14%, 15.5%

Emboldened by the beauty of the 30-minute wash success, I was determined to find the limit and see where the undesirables would finally make their way into my wash and contaminate it with the green leak. I decided to perform a 1-hour dry ice wash in the same manner as the others. Again, a beautiful wash resulted, and the final product looked nearly identical to the 30-minute wash and yielded 16%. I was shocked again.

CONCLUSIONS AND CONSIDERATIONS

The shorter washes in each group were clearer than the longer ones, which is commonly expected. The unexpected was the narrow margin of clarity and color quality of the finished concentrates between each group’s shortest and longest washes.

I believe three factors made the very clean, long washes possible. First, while broken up thoroughly by hand, the material suffered only minor cell wall disruption, keeping the undesirables well contained. Second, through the entire wash cycle of each run, everything was kept well chilled and not allowed the chance to warm or vary in temperature. Third, the alcohol and plant material was separated with great expediency and never squeezed nor pressed.

In general, the yields of both groups increased with longer soak times, as expected. The 10 and 15-minute washes from the freezer were identical, both 1.96 grams. I think the 15-minute wash would have been a bit more if I had been more disciplined and consistent with the amount of alcohol used with every wash. It is apparent in the photos that the 15-minute freezer wash was 2 fl oz short of the other samples. I believe this reduced the final yield of that wash to some extent, but I don’t know how much. The dry ice samples showed an increase in yield to the 1-hour mark but increased at a slower rate between the 30-minute and 1-hour washes. I’m convinced the yields in this experiment were low due to the quality of bud used and can be improved with higher quality buds.

The stark difference between the freezer and dry ice runs clearly demonstrated that the lower temperature of the dry ice QWET immobilizes undesirables and increases color quality. I think using the dry ice performs two processes at the same time. Typically, QWET is done in the freezer, and then, to clean up further, the wash can be put back in the freezer to winterize. Using dry ice temperatures appears to perform both of these tasks simultaneously.

I would encourage those who try the freezer and the dry ice temps and times to use small quantities and explore which method and soak time suits their preferences best. This craft has no right or wrong; it only makes you happy, and your friends pass out. Whatever you choose, crafting with cold QWET will help you make FIRE with ease and win bragging rights!

IMPORTANT NOTE: I used ExtractCraft mats in this post but I do not recommend their equipment.

STAY LIFTED MY FRIENDS !!!

CHECKOUT THE ICHIBAN’S EXTRACTION LOUNGE GROUP ON FACEBOOK

I just don’t like running a $600 vacuum pump when I can buy one for $80.

where do you get an 80.00 pump?

How long do you wash cannabis before putting in the turbo extract crafter?

Same as in the blog post

How much do you break apart the buds? You have mentioned not breaking them up too much if you are avoiding green wash.

I disassemble them as much as possible or as much as I have patience for

do you not decarb?

Please read the decarb post

Just bought the Source and not unpacked yet. Is there a conversion rate to how many ozs/grams of flower you use to what you end up with?

Not really. It depends on the quality of the material, the process you use, what you are making, and how many times you wash the material. Yield can range from 5%-30%

Any idea of the % THC that is extracted by either method?

Thanks

Impossible to say too many factors, up to 100%, down to 0%

How would you use the source to make a tincture with bourbon for sublingual dosing.

I’m using 100% ETOH which is too hot by itself!

Take the oil almost all the way down then mix with bourbon?

I over did it once (turned into goop) and it would not go into solution with bourbon. But I’ll try again and let you know.

That’s because bourbon is 60% water

Have you ever done dry ice QWET with fresh frozen cannabis, as in the buds are removed from the plant and frozen immediately after harvesting without any drying? I have read freezing fresh maximizes terpene retention, so I wonder if combining that with your dry ice QWET could make a very flavorful CO extract. I would think that as long as the buds stay frozen during washes due to the dry ice that the water will remain locked up in the bud. Even if some did come out in the ethanol, do you think that would cause any problems downstream?

too much water content. You can do if you use a freeze dryer with the fresh material first.

Hey! New at extractions! Using the source and dry ice to produce feco for edible or even better sublingual use! Your site has been most helpful and I am so greatful for your effort to educate us novices! So let me ask: i have used your insight to create concentrate tincture using the source but the sting of the ethanol is still killing me, even with the lowest possible dosage! So is there any way i can get sublingual absorbing of my feco, without the ethanol taste and sting? Thanks in advance…

Hi. I’m glad this information has been helpful. Unfortunately thats the problem with ethanol, it’s very aggressive and burns. You could try to add some water. You could put in an alcohol safe spray bottle and spray in the mouth? Otherwise just add the extraction to a carrier oil and use more like an edible?

I found with tinctures at least if i use terpenes the ethanol taste is reduced if not eliminated!

Cant thank you enough for all this experience you have here!!

Thanks for all the great info it has helped tremendously. Do find the Qwet method is the best way for making feco for edibles? And lastly do you think it’s worth doing a second wash when you soak for a longer amount of time.

Yes, QWET for edibles is best in my opinion. I’ve commented a bit about it in the “Cooking With Concentrates” post as well. A second wash viability would depend on quality of material and efficiency of your wash, so it depends. If you have very high quality material and you did a really cold and quite short wash, then a second wash would probably collect quite a bit (I never combine washes). If the material is marginal and you were quite aggressive with the first pass then maybe not.

Hi there,

I ground up my backyard bud in Coffee grinder, decarboxylated in oven, froze ground flower and ethanol , then combined for 24 hours, my wash is quite dark even after running it through Buchner flask w thru 3 micron paper filter w/ 1/4″ of activated charcoal powder on top.

ran through Turbo extractor to concentrate. still fairly liquid and dark, if I do a dry ice “settle out” would that clear up a bit more? or better to try Buchner w DE? using for tincture

If you don’t want it dark don’t grind and watch the exposure time. EVERYTHING in you question is answered in the post you commented on I believe

You used a paper filter and AC in a Buchner? Was it fritted? AC works best in a fritted Buchner with a 1/4″ DE bed.

Sometimes you work with what’s best and other times you work with what you have.

I have found adding activated charcoal prior to filtering will take out most of the chlorophyll

I would filter first so 1) the carbon isn’t wasting time on plant matter that will be filtered out 2) it doesn’t make primary filtration heavier and more difficult

Hi Mate, just about to extract some feco for a cancer patient. Have just purchased the Buchner funnel vacuum flask 1L with 0.45 micron nylon membrane filters will be using iso as the solvent. at which micron can i filter to achieve the best results without removing the needed components. Have as low as 20 micron coffee filters and no in between at this stage. I Appreciate the knowledge. Cheers.

I use 3 micron slow flow filters. I’ve never seen 0.45 micron nylon filters, do you have a link so I can look?

What if using pure tar green extract ..how to add ethanol or clean

Probably too late unless you want to try scrubbing. You can see the details on that in my “Polishing Dark Extracts” post. If you don’t want those green and planty components in your extract its best to avoid them from the beginning of the extract for best results.

Will this work with processed stick dark oil?

Apologies, I’m not clear on exactly what you mean here

My plants were processed by a company and came back as a dark.green very thick sticky oil ..only way to transfer is lightly warm..I would like to take to clear..and not destroy thc

Sounds like your expectations are outside of realistic process and extraction components. You may need to do some studying on the topic of extraction and what the final form of extractions look and handle like.

I put bud and ethanol in freezer. I use my first wash for vape concentrate. I keep the jars of washed buds in the freezer and later rewash the same material; this second wash I extract and decarb and use for sublingual or patches. I’ve also done this a third time. How will I know how many times I can do this to the same material? And how long can I store this material in the freezer in between these washes? I’ve been determining my time frame based on my daughter’s need for the various medications. (Also, just by my nature, I hate to throw anything out that may still have some value, even though I have a fairly plentiful supply!)

I’m not sure where to ask this question and my searches on the FB page don’t come up with the answer.

I’m also beginning to think I should do these washes as close together as possible and then store the wash (keep it in the freezer) until I can get time to process it in the Source. Then once it is extracted and air purged I guess I should collect these little batches from the Source until there is enough to make the medicine in larger batches. (Until now I’ve been using the small quantities each time just as she needs more vape, or sublingual or patches.)

I’m just wondering if a) my process is making a less effective medicine either because I wash it too often, and/or wait too long between washes, and b) if my process can in some way be made more efficient.

My daughter continues to say the medicine works even on the third wash cycle. I’m not using it myself so I can’t make my own judgement on the quality…but love the plant and the smell and very occasionally smoke a little. My harvest seems to have cured well and have a long shelf life! (That’s what I have tested for myself, using product from summer 2018 harvest. So growing every other year is good.)

Thank you so much for all you share and and teach AND for helping me figure out how to make medicine for my daughter.

It’s all about the efficiency of what you are after, I would recommend reading my post on Yield and Extraction and the balance of the two. That is what it basically comes down to. If you are planning on doing more than one wash I would do them back to back, you can always store the wash instead of storing the material.

Thanks for the great info.

Did I miss in the post where you said how cold your freezer is?

I only ask because my stand alone freezer gets down to 0°f and I was wondering how long of a wash I could get away with at that temp? My end goal is a wax that I could dab.

The freezer I used is a regular stand alone freezer

Thanks, I will be giving my first try with the source this weekend.

Oh, what an excellent site. Thanks for sharing…

Thank you for your fantastic treatise!! I’ve learned a LOT.

I’ve been told I’ll damage my vacuum pump if I use it to remove the ethanol from extract. How do you avoid this? How do you recover the ethanol? I’m familiar with using a condenser when evaporating ethanol with heat, but I’m unaware of how I would recover it when removed by vacuum.

I assume you mean purging in post processing terms and not primarily ethanol recovery. It kind of depends on volume. If you are post process purging 1g at a time in a 1 gallon tank you aren’t going to pull much. If you are doing many grams and have the pump pulling the whole time you will catch more ethanol vapor into the pump. To avoid you can get a cold trap

Maybe stupid question, but cant find answers… Can i use wheel filter? or are there any other options for good filtering? Or could i just buy 5micron pp filter and use it without buchnel funnel (i dont care about time)?

Any filtration method that’s is food safe and doesn’t introduce chemicals nor contamination works

“2 wire mesh coffee filters with a 150 micron screen sandwiched in between. The fast, rough filtered wash was then put through the Buchner funnel filter a 2-3 times until it was crystal clear, then into a mason jar”

What size Büchner funnel? 120?

You mean the filter paper micron size? Fast flow is 20u and slow is 3u

I should also add, I am now just laying a larger 40u or 80u mesh over a kitchen strainer.

Dear IchibanCrafter,

I have been reading your blog and soaking up all the information.

This takes money, time and effort.

Thank you so much for doing this and sharing this wealth of knowledge!

I am reading everything and would like to make vape cartridges, and following all your procedures and tips.

I don’t own an extractor and/or vacuum yet, just reading for now 🙂

Just a quick question on the QWET.

Where do you purchase your Ethanol and are there different “brands” you prefer?

I do have 190 proof Everclear that is 95% ABV.

Can I use that as wash liquid?

I have heard different opinions about Everclear.

Any thoughts?

Ron

Everclear is fine. I use “42o Extractor” (www.42oextractor.com).

link is dead. I found a mystic mountain distillery site in Co, but it had nothing about 420 extractor, so I’m posting this instead: https://www.totalwine.com/spirits/white-whiskeymoonshine/mystic-mountain-420-extractor/p/212666750 so people have an idea of what it looks like. Looks like it’s a bit cheaper than everclear. I have no relation to Totalwine and am not endorsing this vendor.

This link works https://42oextractor.com

I was wondering if it would work to put some of the dry ice directly into the cold Alcohol before doing the wash.

People often want to do that but it’s not as good of an idea in reality as it is on paper. Forcing C02 into the wash, uncontrollable bubbling action, and undesirable contamination are just a few reasons why it’s not really a great idea.

Thanks for your reply and also thanks for this excellent Blog.

I was thinking that I would wait until after the bubbling had ended to use the alcohol to do the wash but I did not know that there might be a possibility for contamination from the dry ice so I will skip that idea and use your procedure. This is my first attempt and I only have 15 gm of dried & cured small buds that I will be using.

My objective is to make RSO/FECO with Everclear but I don’t want the end product to be full strength so after the wash I was going to boil off only ~ 90% of the Everclear. After that I was thinking that I would like to add in an equal amount of Olive Oil or MCT oil for palateability and to achieve my desired dilution. Can I add the oil right at the end of my boiling and will it combine fully and not separate out? Which oil would you choose to do that? I do have a heated stirrer to use for that step.

Have you read this? https://extractcrafter.com/2020/10/16/cannabis-tincture-and-tincture-concentrate-a-great-way-to-medicate/

No I had not read that article yet. Thanks for pointing it out to me. I definitely want to make the “clean Golden Tincture” version to cut down on chlorophyll and I was hoping for sub-lingual absorption. From reading your article I learned that once it’s combined with an oil carrier sub-lingual is out the window so I guess my best bet is just boil off most of the alcohol and go with that. If it burns too much then I can cross that bridge when I must. Thanks again for your help. MUCH appreciated.

I think it is best to accept the fact that using the carrier oil takes a little longer than sublingual. I actually am not a huge fan of the sublinguals, defiantly feel like better and more full results with the oral ingestion with the oil and some say even more so by adding some sunflower lecithin.

Hi Ichiban,

First, thanks for your info. It’s been invaluable and so refreshing to have a reference that isn’t mostly or partially full of $%^&* like so many other sites.

I’m a proud Source Turbo owner and have made a few dozen cannabis tinctures so far. My goal is maximum yield in as few washes as possible, and I’ve been having good success with extreme agitation of decarbed flower in Everclear at room temperature using a magnetic stirrer. I limit the amount of flower to 7g and use around 150ml of Everclear in a mason jar. As the end purpose is for ingestion and not vaping, I don’t mind extra ‘stuff’ in it. After stirring the wash and flower, I have been removing the flower and putting the resulting wash in the freezer for several days, and then performing more filtering before putting it in the source turbo using a few coffee filters. The final product is then put in a tincture and ingested. I’ve recently purchased the Buchner setup but haven’t had a chance to use it yet.

With that said, it’s gone quite well. My complaints are few, but the perfectionist in me needs to address them.

1) As I reduce the final product in the source turbo more and more, I’m running into problems with ‘gunk’ at the tail end of using the tincture. As I measure the potency in drops (often two drops will be plenty for a single administration), even a little gunk in the dropper confuses my estimates of potency (and thus of dosing) in the last dozen or so drops. Getting rid of this final gunk would be awesome.

2) I’d also like to reduce the time it takes to cool down (3 days in a household freezer seems to work best) before filtering. If I can even get it colder and help the filters better do their job, all the better!

As the cold from dry ice would presumably really reduce the yields I’m used to and require a bunch more washes, I’m not sold on using dry ice in solution with the flower. But using dry ice in solution after flower removal, and pre-winterization, just to get it really, really, cold quickly, sounds like a good idea at the moment. I’m very tempted to plop some dry ice in the mason jar, leave the lid off and use that to cool things down before filtering.

In the comments above you mentioned that CO2 and agitation would be an issue for putting dry ice directly in solution with the flower, but this situation seems different as the flower isn’t present?

Good idea, or is there a problem / better way? Does getting it as cold as possible greatly assist with filtering? Who knows, maybe I’ll start using the Buchner with my old method and not need to care?

Thanks.

1) The gunk comes from soaking too long and/or too warm. You said “I don’t mind extra stuff in it.” That gunk is your extra stuff. If you don’t want it in there then avoid picking it up when making the wash. Maybe checkout my post “Ethanol Extraction: Complete Breakdown” for lots of tips.

2) Checkout the post I mentioned above, that should help. Putting dry ice into the wash is a bad idea, don’t do it. All beginners think this is a good idea, if it were then that is how I would be doing it in the articles here.

I have the same question.

which question?

Thank you or all the informative research, this is such a great test that you have done and shared! I have used both dry ice and freezer with same ending color results. Right now, I do not have a vauum still but put together and simple, or air still, in its place(Erlenmeyer flasks, distilation elbow, Graham condesor, hotplate w/ stirrer, etc.). This has done a good job of recovering the ethanol at a good rate but obviously sacrificing some of the terpenes due to the higher heat it requires. I compensate by reintroducing them in post processing This leads me to two questions.

First, at what point do you, or should I, stop ethanol extraction process? When it is thickest or early enough so that it is still easily pourable? I’m always wondering if I’m stopping to late or too early.

Also, what is your purging process? How much heat and how long do you typically purge for until you are satisfied with the final product.

Cheers!

ps. I extract only to make cartridges, if that helps with the questions at all.

Thank you for the kind words. I would point out that the extra heat isn’t only blowing off terps, it leads to increased oxidation which is a quality killer.

I think you can find the answers to those questions in a couple other articles here on extractcrafter.com. The processing questions are covered well in the Ethanol Extraction: Complete Breakdown post and there is a helpful post on making carts as well, Pure EHO Carts with Jar Tech. Lastly, if you want to improve your quality game the DIY Vacuum Still posts will get you on the right path.

I’m glad I found your site. I’m looking to improve on my crude RSO, and you have provided some great information.

I was wondering about starting with a sifted kief product instead of broken flower. Someone must have tried this. Any ideas

Check out some of my other articles. Particularly this one https://extractcrafter.com/2021/02/13/hash-rosin-and-ethanol-extraction-a-cannabis-ecosystem/