By Troy Ivan

ibc@ichibancrafter.com

Making a great smokeable cannabis concentrate yourself at home, with good color, great taste, and unbelievable potency is easy but you must understand some basic fundamentals of how to keep the green out of the extraction. Using ethanol for cannabis extraction is very effective, but has limitations due to its hydrophilic and polar nature. Meaning it likes to pick up polar and water based molecules and that’s not good for cannabis extraction. We don’t want polar, water based undesirables like chlorophyll, waxes, paraffin and fats in our extractions so we must take steps to limit the contamination. To limit the uptake of undesirables we use a method called Quick Wash Ethanol (QWET). QWET involves freezing ethanol and cannabis separately before the extraction, controlling the duration the cannabis is exposed to ethanol in the wash, stopping it from turning green and instead producing a beautiful golden wash and amazing concentrate. In this blog I introduce the use of dry ice to super-cool and increase the effectiveness of the process and take QWET to the next level.

WHY FREEZE FOR THE WASH?

Performing a wash with ethanol and cannabis at room temperature allows the ethanol to quickly attach to polar undesirables in the cannabis and carry them into your extraction turning it green and unsuitable for making a quality vapable concentrate. To avoid picking up undesirables in the wash, freeze the ethanol and cannabis separately overnight. Freezing cannabis immobilizes water based compounds making them difficult to pick up. Freezing ethanol also helps in two additional ways. First, it keeps the cannabis frozen during the wash cycle. Second, when ethanol is lowered to below freezing temperatures it’s pickup of soluble components is substantially slowed and the ability to attach to frozen water based components nearly eliminated. This is very useful because to make the best smokeable concentrate we have to eliminate undesirables and maximize the pick up of the soluble components we want like THC, CBD and terpenes.

Using a freezer to perform frozen QWET works with the general limitations of 10-min wash for flower and no more than 3-min for beat up trim. If executed with care, using quality buds broken up by hand with minimal cell wall damage it can be stretched to 20-minutes. For best results it’s very important to keep everything frozen the entire time and gently shake the mixture periodically to make sure a saturated boundary layer doesn’t form around the plant material.

There are two situations where this process has weaknesses. First, using beat up, chopped up trim with a lot of cell wall destruction still tends to leak green and quickly pick up a plant flavor. Bad trim can leak in as short as a 1-minute wash. Second, the temperature of a typical freezer will not keep the water elements immobile very long and will warm quickly once removed from the frozen environment. Dry ice can combat these weaknesses to enhance the immobilization of undesirables and slow pickup further.

COOLING WITH DRY ICE

The average recommended temperature setting for a freezer is 0°F compared to the surface temperature of dry ice being nearly -110°F. That large difference in temperature give us the margin necessary to hit the recommended wash temperature of -40°F, substantially colder than a freezer’s ability, providing absolute immobilization of water compounds and slowing pick-up to a crawl.

To use the dry ice method here is what you will need:

- Ethanol – 190-proof (95%)

- Cannabis

- Small cooler

- 2 ziplock freezer bags

- 2-4 lbs of dry ice.

Place the cannabis in one ziplock and ethanol in the other. Put the dry ice, cannabis and ethanol into a small cooler. Restricting the amount of open space in the cooler will help with cooling. It should take about 1-hour to sufficiently freeze the cannabis and cool the ethanol to -40°F.

SUPER-COOLED WASH

When the cannabis and ethanol are suitably cooled combine them and keep the mixture in the dry ice environment for the duration of the wash. You must gently agitate the mixture every couple of minutes to move saturated ethanol away from the plant material and fresh ethanol in. If you’re using beat up trim use very light agitation only, but with quality flower a little stronger agitation is beneficial. Once the wash is finished continue with filtering, evaporation, and post processing as you normally would.

-Dry ice wash using poor quality choppy trim-

To test the dry ice wash tolerance for poor quality choppy trim I tested the difference between 3-min and 10-min washes. I like using inferior materials for process testing because it clearly gives the worst case scenario.

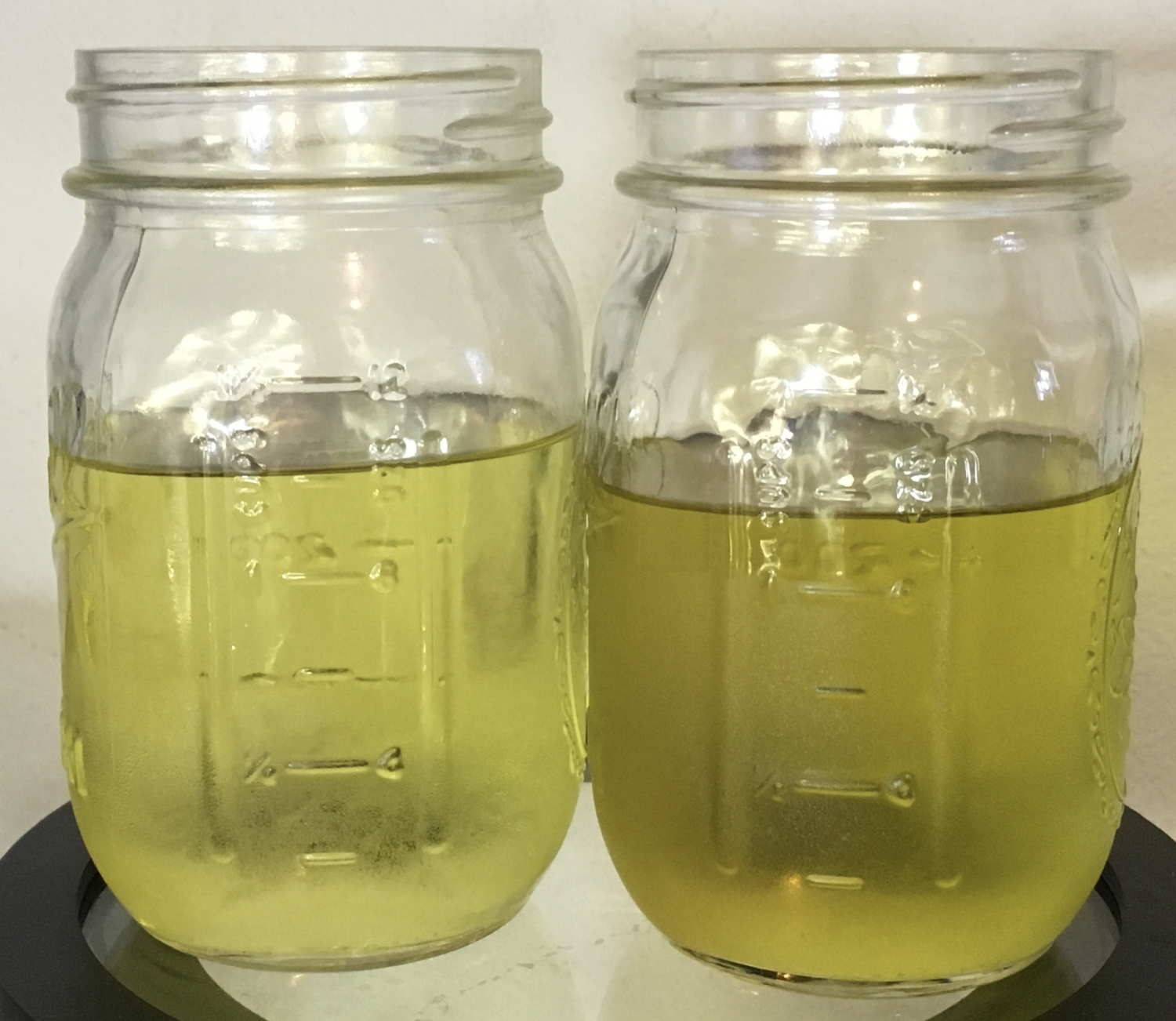

Both wash samples came from equal amounts of ethanol and 29g of poor quality Jack Frost trim. For separation and filtering I used a Buchner funnel under vacuum to separate the cannabis and ethanol as quickly as possible to minimize the risk of green leak. Both samples in the photo were approximately 10 fl oz with the lighter 3-min wash on the left and darker 10-min wash on the right. There’s an obvious color difference between the wash on the left and the one on the right.

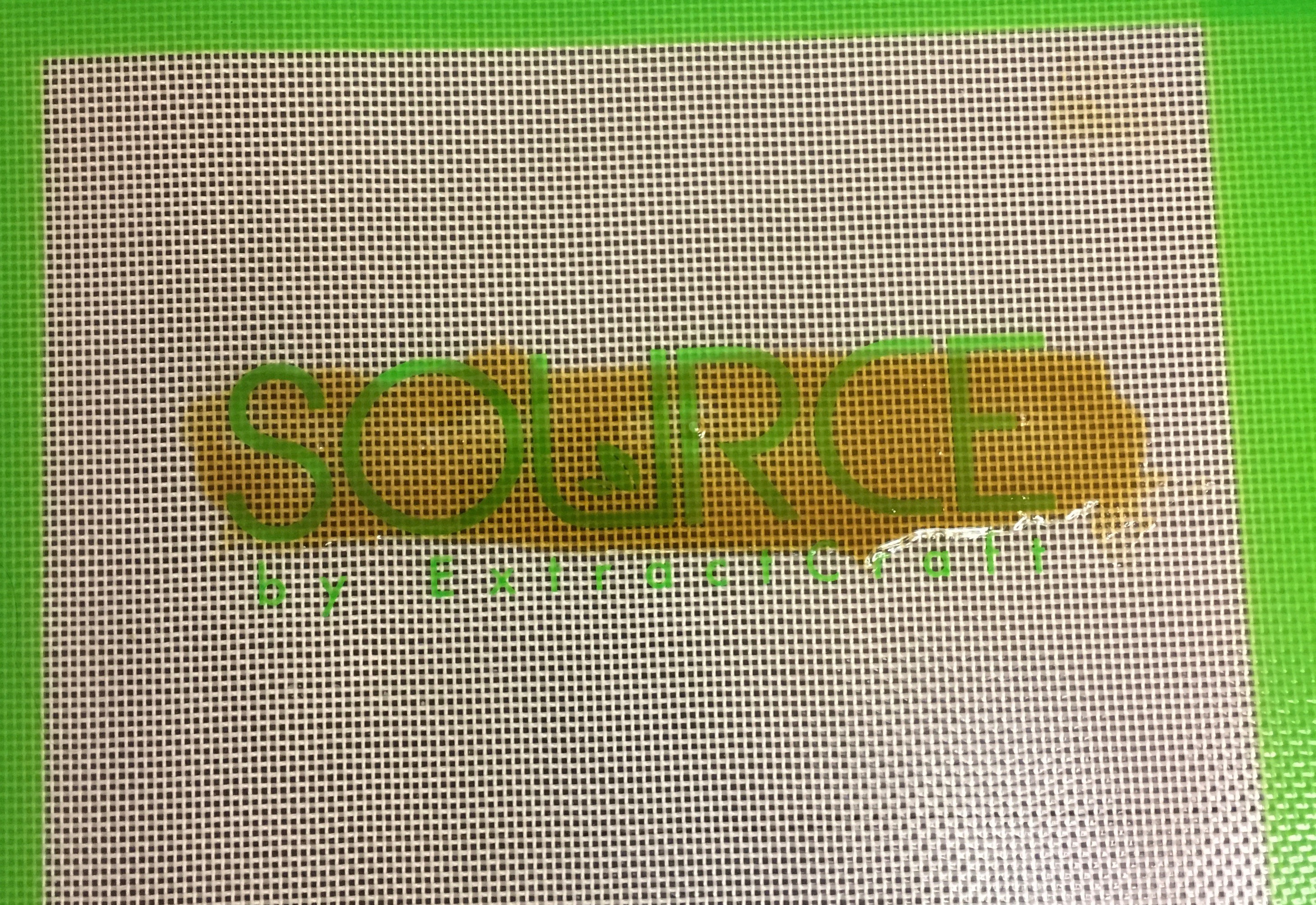

After evaporating the alcohol at 102°f for about 3 hours using the Source by ExtractCraft the oil from both samples looked remarkably similar in every way except volume. The 10-min wash produced more volume and appeared to be of the same nature and characteristics as the 3-min wash with no apparent additional pick up of undesirables. That means the the difference in the washes was not a simple color difference but due to increased density of desirable component pickup.

Lastly, the oil was purged using a standard vacuum chamber and single stage pump operating between 90°F-100°F for 72 hours ending with very interesting results.

Both samples appeared identical in quality but weight was clearly a different story. Fully purged the 3-min wash sample was 0.9g and the 10-min wash sample came in at 1.4g, more than a 50% increase (yields are low as a consequence of using scrappy starting material). The 50% gain came with no discernible detrimental effects of the significantly longer super-cooled wash.

-Dry ice wash using quality flower-

Using flower provides some distinct advantages. Flower has the best trichomes in the most concentrated areas and these are what we’re obviously most interested in targeting. Also, the layered fashion in which the buds grow make it easy to break up by hand without causing much cell wall damage and protecting the extraction from green leak. Breaking up buds by hand (don’t grind) is important to allow the ethanol access all surfaces and flow freely over the cannabis during the wash. Compared to trim, flower can definitely stand up to extended ethanol exposure and slightly more robust agitation, both of which are instrumental in harvesting as much THC, CBD, and terpenes as possible.

For this experiment I used 14g of Bubba-Cross flower for each wash. Knowing flower can stand up to more aggressive treatment in the wash I started testing with a 15-min wash, and it came out beautifully. I then stretched it to 20-min, then 30-min then 1-hour. I was amazed the wash could be stretched to an hour, and could have easily gone even longer, but most importantly all the washes maintained the same color characteristics! The color characteristics are uniform however the density of pickup clearly increased with the longer washes (left to right: 15 min, 20 min, 30 min).

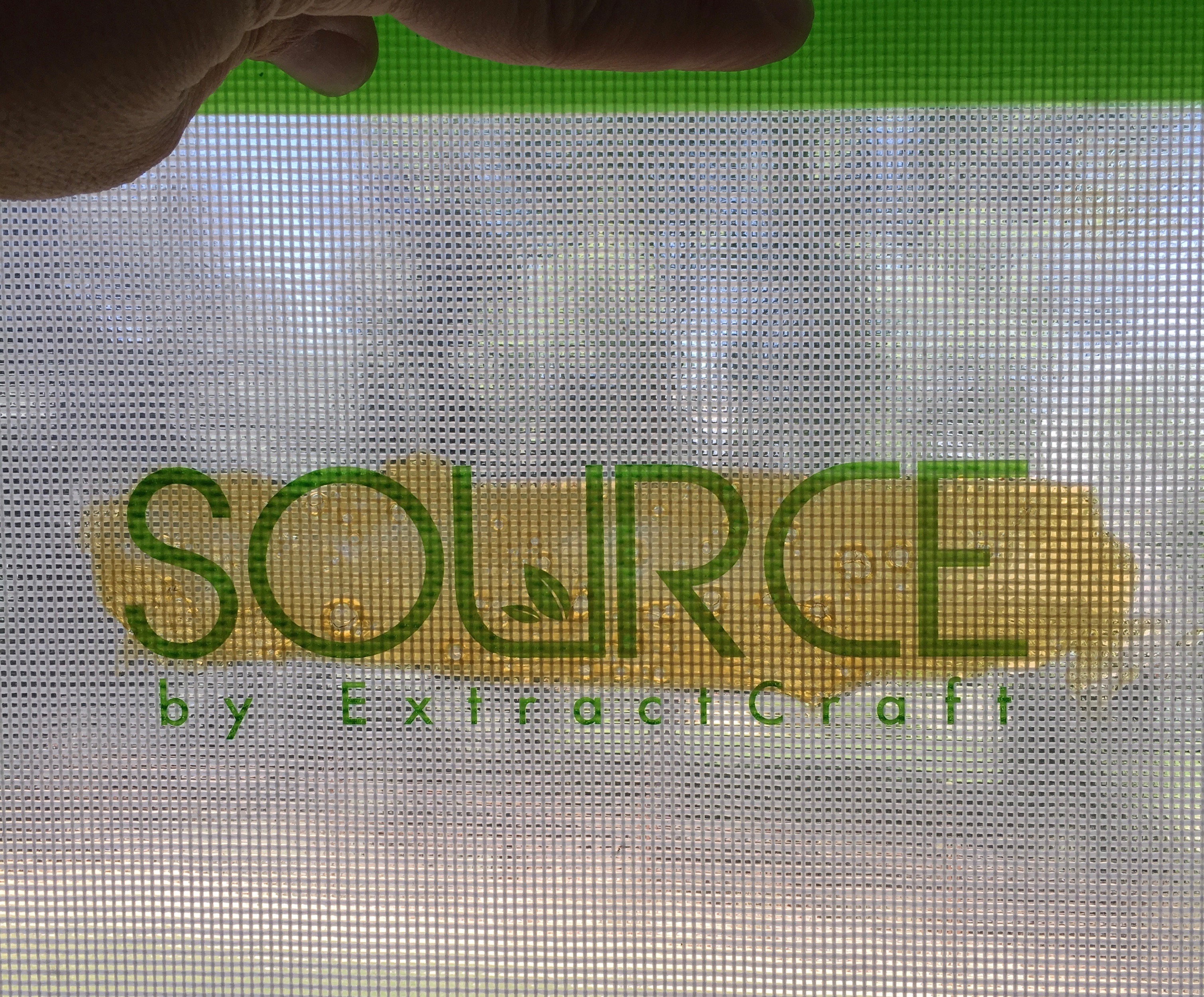

To process the extractions I used the Source Turbo by ExtractCraft (www.extractcraft.com) to make the strongest oil possible then finished in a vacuum oven at 90°F. In the photos below you can see the result of the 1-hour wash. On the left is the oil straight out of the Source Turbo and on the right is the finished purged product. That’s from a 1-HOUR WASH Y’ALL!

In terms of quality and yield it’s the same observation we had with the choppy trim results. Quality didn’t suffer in any real observable way but the yield increased tremendously. The yields from the 15-minute wash to the 30-minute wash increased from 11.5% to 15.5% providing a 35% increase in yield for the exact same material. The 1-hour wash showed a small increase in yield at 16% but the gains in yield seemed to be slowing.

CONSIDERATIONS AND TAKE AWAY

Dry ice definitely makes cleaner QWET extraction possible and almost easy. The low temperatures used with a dry ice wash defiantly slows the absorption and collection of the desirable components as well as the undesirables. Some people contend that when using dry ice to wash good flower it loses some flavor and terpene profile. I don’t know to what extent this is true because I don’t have testing lab access, but to my experience I think it holds some merit. Dry ice extraction compared directly with freezer extraction from the same material has shown me a small decrease in flavor, but no apparent change in potency. Conversely, freezer QWET will sometimes have a slight plant taste while a good dry ice QWET never does. With everything we covered in mind, I think the take away is with trim absolutely use dry ice to make good trim into amazing smoke, decent trim into something very good, and throw away trim into something useful and valuable. With flower it’s debatable and you are going to have to experiment and try on your own to determine what is best for you because we all have very different preferences.

I have another blog that ties into this one that pits using the freezer against dry ice and compares the results. If you’d like you can check it out here Cannabis Oil QWET Extraction Battle of The Wash: Dry Ice vs. Freezer

Caveats:

- “Super-Cooled” isn’t technically correct as far as science is concerned but it sounds so super-cool that I couldn’t resist taking some literary liberties and bending it to my own demanding cannabis needs.

- I’m no expert and still learning, so if you see something blatantly wrong or silly please point it out.

Hi Ichiban, great site, I found it looking for more information on this exact process.

The different wash times was very interesting. I would imagine the 3 minute is a little more potent? Both look great, what’s the word on the consumer end, good taste?

Also, I’d be interested to see some item amounts/costs. How much alcohol per batch (29g) was used? What % of your alcohol are you reclaiming? How much dry ice was used?

Hi James,

Thanks for checking out my stuff. Those are all great questions, and you may be disappointed to know that I don’t have perfect answers for most of those questions the answer is “It depends”. Having said that, I will share with you what I do know.

The 3-minute wash would in theory be more potent than and 1-minute wash and the 10-minute wash (assuming comparable clean wash) would be more potent yet. Because the end products are coming out visually comparable I have to contribute a lot of the yield difference to potency. With that said, a typical 3-minute was is said to remove 80% of the potential THC so how beneficial the extra time actually is isn’t proven yet, but appears beneficial. I would love to have access to test that, but, in colorado you can only test material if you have the applicable license. Unfortunately, I don’t have that license.

Considering my experimentations have been with low quality trim I think the taste has been pretty good. I actually took this process to the next level a couple days ago but running the wash through the Buchner Funnel with a slow feed filter three times then winterized it before evaporating. All I can say is WOW! Huge improvement. The oil came out smelling like it was a nug run. I highly reccomend taking the extra time to do this. Its never going to be as perfect as a nug run, but it was pretty dam good.

Alcohol per batch, it depends….. It varies depending on the starting material. For example, the cruddy trim I’m using is quite fluffy so it takes extra alcohol to fill the extra space, so I have to use around 10-12 oz of ethanol to wash 29g. On the other hand, if I use tight, dense bud I can use 6-8oz for 29g. Basically, you need the ethanol to cover the cannabis well and be able to work its way all around it. I’m currently trying to work out the exact saturation goings which I think is around 4g per 8oz of Ethanol but I need to consult someone who knows this well.

Reclaim is very consistent. Assuming proper eye-balling portions of Solvent covering plant material the absorption rate is around 30%. (you don’t want to try to improve this by squeezing the material to wring out more alcohol, all you end up doing is ruing your run with waxes, paraffins, and chlorophyll). Then using the Source I am able to reclaim about 95% of what would normally be lost to evaporation.

Dry Ice is going to depend on how much material you are going to use, how big the cooler is and how you put the material in. I have found using a smaller cooler, with the plant material and ethanol in ziplock provides the most surface exposure for cooling while using the least amount of space and requiring minimal dry ice. Doing 29g in a small cooler can use just a few pounds of dry ice.

Hope this helps!

Thanks again for staying with this post. So nice to come back a few years later and see that you are still answering questions.

I am wondering what is the cleanest and safest way to turn this product into a cartridge or e juice. I am not too familiar with ejuice but it seems like everyone is adding stuff that I don’t want to smoke. Thanks

I would checkout the cart post to start. Then I would look at CCell carts that handle high viscosity oil

Hi just thinking “out loud” but wouldn’t it be beneficial to do 2-3 minute washes? If in fact it is more potent, get the 80% from the first wash keep it cooled and the remaining 20% from the second wash mix the alcohol cool together and then evaporate off the alcohol? (After filtration and warming to room temperature)

Hi Curious!

For the most part that is standard operating procedure. What I found is that when I kept the temp at around -40f for the wash up to filtering, I found little change to no change in quality of the wash between 3min and 10min. But there was a large pickup in yield. Obviously, this requires a lot of care and any sloppy procedure is going to have tremendous negative effects with a 10 min wash.

Conversely, every time I have executed a second wash, like you are inquiring about, I always have a lot more green leak and plant smell/flavor. This will also be accompanied by a hight CBD and CBN ratio of that wash. For me that is not what I am looking for and would keep those two washes separate as the first wash would be more head high, and the second wash would produce a more sleepy and sedate affect. However, if you aren’t as particular to green leak, and you wanted an end result that is both head high and sedative in nature, what you are proposing may be a good option.

Great question, and thanks for asking!

Hi this is randy wiser (see above). I started using the dry ice after seeing it on YouTube. I have used up to 4 ten minute runs with the same material. Very low to no green leak. I also mixed all the runs together and placed in a countertop still from Nutrihome to reclaim as much as possible as I am using 200 proof ethanol from extractrahol. They also sell an organic 190. Available in gal, 5 gal, and 50 gal. Recently bought 200 5 gal that turned out to be less expensive then Everclear. I mix the resulting extract with MCT AT 1 gr to 1 oz, and use sublingually throughout the day for arthritis and pain. I mix in high CBD oil 1-1 for sleep.

Hey ICHIBANCRAFTER, thanks for the acknowledgement. Observation, are you concerned at all about using plastic bags? Especially since you are not able to have it tested. It seems risky to me. I have been storing and processing everything in mason jars, just don’t trust the big plastic companies for this use. I am concerned that the 190-200 ethanol will extract from the plastic as well. Also a hint, if you place your ethanol and dried material on the bottom of the cooler, and the ice on top it will freeze everything faster. I lay the jars on their sides and stack the slabs of ice on them.

Plastic for an hour or two doesn’t bother me. Ice on top is a good idea.

are you not worried about the mason jars cracking with the dry ice on it?

Am I worried, yes. Have I had a problem yet, no. Most of the time I am using ziplock bags in with the dry Ice. They also now have reusable silicone ziplock type bags that can go in with the dry ice as well as in the oven.

just curious why there is an ever clear bottle in the pic? Are you using a denatured alcohol instead of pure 200proof ethanol?

Used 95% ethanol, so in this case I was using Everclear

Great info. I did a quick freezer run without Vac Purging. Great product! Defiantly getting a vac though!

What do you think of using 200 Proof Ethenol (Extractohol)?

Quite honestly I’m not sure. I haven’t used that brand but I hear good things. I haven’t really focused on 200-proof enough to give an opinion. That should definitely be on my list of things to do.

Thanks for posting I enjoyed reading it. How about tossing the dry ice into the ethanol, cooling it to sub zero temps, and tossing in some fresh frozen nugs popcorns and sugar and letting it soak at sub zero agitating it around and letting the non polar part of the alcohol do its thing while the polar is frozen, conforming temps with a temp gun. Then straining it through some mesh into your distiller or apparatus of choice to evaporate. Strain while dry ice possibly still chunky to ensure sub Ero temeperayude. You should be left with some pristine oil. Oh and also do this in a stainless steel pot or rubber ice bucket to avoid breaking glass or plastic due to sub zero temps. Seems like the most fool proof way to avoid chlorophyll extracting. That stuff is kinda hard to digest as well as mentioned really harsh to inhale.

Hi there! Thank you for your input, it is very much appreciated! May I ask if you have personally executed this process? I have wanted to experiment with this further but haven’t had the time to go back to it. I tried this process one time and it was so violent that the wash turned green even with the subzero temps because the plant material was bashed around so much by the hyper activity going on in the vessel I was using. If you have done this yourself and have any tips I what I may have been doing wrong please let me know. Thanks again!

Hi. You are very welcome. i haven’t executed it yet though was going to attempt it pretty soon. Maybe you added too much dry ice too soon. I got the idea from a youtube video as well as reading about ethanol dry ice baths that are commonly used in laboratories. The you tube link is https://www.youtube.com/watch?v=-x3mV0PUxDw&t=55s tbough just be aware that the video demonstrates it in a disorganized and messy manner and also does not provide what the end product looks like or how it turned out. All that being said though, I still liked the idea and have been reading and reading about it and don’t see why it wouldn’t work. I am curious on the exact steps you took like what kind of vessel you used to perform the extraction. I have read that only stainless steel or rubber buckets should be used because the sub zero temps can crack glass or plastic. Feel free to share and I will do my best to video the process as well and provide data on how the extraction goes.

I’d love to see how yours comes out. I am super busy on too many things to get back to this in any timely manner so your demo would be awesome. I just used a large mason jar, probably not the best choice, but it was just a quick and dirty experiment to see what would happen. I also used trim which would have been more susceptible to green leak with all the agitation. My main problem with the process is the lack of control and overly aggressive nature of the interaction between the ethanol and dry ice. I don’t really see any gain when you can super cool the ethanol, under controlled circumstance in about 60 minutes or so. If you come up with a great solution I will be very happy to see it, best of luck!

I have done it as Hesaidgrow outlined and it turned out fantastic.. I used 99% isopropyl rather than ethanol, filled up a vessel halfway with iso, tossed in a few large-ish chunks of dry ice and let it boil until it reached it’s lowest temperature at which time the boiling will suddenly reduce in intensity. While the alcohol was cooling, I had my material on top of another piece of dry ice that had been cooling for about an hour beforehand. While still in the freezer, added material to alcohol and stirred it in to where it wasn’t riding the surface and was swept up in the current from the boiling dry ice. Left it for 25 minutes to self-agitate and transferred it to pyrex baking dish after course straining then paper filtering. The filtering was a bit of a panic as the filters do not like passing liquid that is causing frozen condensation, plugging up the pores in the paper. I ended up having to use a needle to poke some small holes in the filter after the solids had settled to get it to drain, trying to do so before the solution rose in temperature to the point it would start pulling green. I would recommend using a fine mesh filter rather than paper as the final media to avoid the issue I had! After filtering, gently boiled off alcohol on a hotplate in a well ventilated room, on top of a catch pan to contain everything in case something went wrong such as the pyrex breaking and contents igniting.

awesome……. i was definitely planning on using a fine mesh / bubble bag… that sounds great though.. the only thing that has been on my mind is are there any temperatures that are too cold for extraction? freezing the alcohol and the material before hand and ensuring those are cold are important. and as far as dry ice goes., i would probably just approach it in not throwing a whole bunch of it in, but just enough to keep the temp below zero

I’m not sure if there’s a temperature that’s too cold, but I can say that I left the dry ice in the alcohol for a good 30 or 40 min before starting and I’m quite certain that the alcohol was as cold as it could get in that dry ice.. almost appeared thick in consistency. Given that, the yield at 25 min soak time was excellent and the color was super light yellow liquid. Final result is blonde.

wowzas… so great to hear….. when i did only frozen (not dry ice), i got somewhat of an amber which was beautiful too, but blond is also good.. That was with dry material.> This time I am going to use Fresh Frozen.

Since there is no decarb, I am new to this, using indy hemp and cbd extract, looks like combustion is the end delivery – so decarbed then.

What are good entry level ways to heat/consume this end product? Maybe what is your experienced favorite? ie best for longer term use?

Know this is a bit off topic…

This end product will not be decarbed. The decarb happens when you smoke/vape. I use a vape/wax pen mostly. Many dab or make cartridges. Is that what you are asking?

I know this is a little late, but just curious but decarbing it first doesn’t increase the potential potency using this dry ice method? I was intending to make an e-juice in the end

I don’t know what that means

Kudos for writing the best piece I’ve read on how to gain the purest extraction possible. The commmet threads also offer excellent insight.

The one factor that remains undetermined is the optimal soak time and, as such a critical component in the process, it needs to be determined. My hunch from experience and what I’ve read here, suggests it’s much longer – under the ideal conditions you’ve detailed – than has been considered.

The ideal is to continue testing, increasing soak time by the same amount (15 mins increments?) until the quality of the wash deteriorates perceptibly. Yes, determining at what color shade does one draw the line is subjective, but that doesn’t limit how critical it is to finding a generally acceptable line. As you increase your (pre-deterioration) soaktime, presumably you’re yield will increase as well, keeping in line with the results you’ve shared with us. You’d do this for both bud and trim, ending up with a definitive, fully optimized process with no guesswork involved. Until then, this is a fabulous start.

Yes, those are all great points and there are actually almost an infinite number of considerations that could be added to your suggestions, and then someone would add to that. This post was not meant to be, and I don’t intend on making, a full comprehensive analysis of every component. This is, and was written to be, a simple introduction to the concept and I would encourage anyone with further interest to go ahead, experiment, find interesting results (not questions), and report back and share with the community to lift us all with contributions from all of us. If you get a chance to answer any of your curiosities yourself please report back and share, it would be greatly appreciated by all.

Yo Ichiban thank you so much for all the free access to this awesome information! I was going to start my first extraction with the source turbo and dry ice qwet method using good trim and fire flower mixed in, probably 1.5-2 oz (or as much as can fit in quart mason jar lol)…Now that you’ve done this many times, do you suggest using mason jars in a small cooler instead of the ziplocks with dry ice? Or do ziplocks allow more cold to absorb? Also do you still suggest a 20min wash in the cooler w/ dry ice once plant and alcohol are mixed? I have the buchner funnel and proper filter paper w/ two different grades. Im hoping to get some good pull and snap, or invest in a small vac chamber if the final product isn’t where i’d like it to be…Thank man for all your time and hard work and helping out!!! – Joseph Hauser Persephone’s Farm

I use a lot of ziplocks

All I will be trying a version of this, this week. I do have access to a lab so I will be able to put some analytical data behind the experiment. A few thoughts though, after XX minutes all of the canabinoids terpenes etc. may be extracted. After that, (XX+YY minutes) the only materials being extracted may be polar, or undesirable or terpenes. my point being don’t let color be the deciding factor in a complete wash. Experience and testing should indicate a complete wash.

I agree that you have to experiment, also the input material will make a difference in wash time… now after doing many runs I wash for one hour in dry ice -40degrees and shake often. If trim won’t shake as vigorous. But the color darkness may be more amber but any green is undesirable. I’ve been pulling hella terps in my extractions and getting between 15-20% return. Very satisfied.

My question is regarding de-waxing. The impression I get from studying is that de-waxing to 4 microns in a Buckner filter improves quality of the end product, but at the price of losing terps and flavor. Do you have experimental data or an opinion on the possible loss? If terps are lost with the wax can they be recovered by maybe steam extraction and separation? Lastly, in your article you mention filtering twice then winterizing. I thought they were the same thing. During your 2 filtrations what micron do you use?

De-waxing and winterizing serve the same purpose. If you get a chance to read the winterization post I have here it may clarify some of the specifics. Waxes and lipids always have some degree of terpenes attached to them and you will lose in a winterization process. The trade off is you have a cleaner and more potent end product. Capturing terps, separating, and reintroducing is a big process to do at home. If you want to reintroduce terps I would consider buying some of the isolated terps or prepared profiles. Winterizing only requires a larger micron like a 12 micron and for final filtering I use around a 3 micron.

If your goal were the inclusion of the maximal amount of Terpenes, even if it was at a cost of some Lipids/Waxes remaining, would you stick with a Freezer Based wash over a Dry Ice Wash? I’m desperately trying to avoid the need for any added Terps.

It depends. In some cases yes, in others, no

Amazing article, thank you. I’ve so wanted to know this exact information for a while now. The comparative info has cleared up any lingering doubts about how long you can go at subzero temps. Will definitely be useful for most of my processing but really glad to know it impacts on terpene at those temps! Confirms a lot:) Cheers:)

I dry sift 120 micron then use hot ethanol to dissolve the tricombs to make oil. Then filter through celite and carbon.

I figure dry sift first is more efficient than washing all that plant material.

Have you ever done your super cooled process on just the kief ?

Yes, it works well. The only thing about dry sift only, while it gives you a very clean product it also leaves a lot behind unless you get very aggressive with it, then you have a ton of plant material and have to give up efficiency by later trying to scrub it out. Its all trading one efficiency for another

Thanks. I figure I’d wash and agitate it very well for a while to get all the surface area contact then quick vacumm filter it through a large buchner with a activated carbon “cake” on top of a celite cake to separate the solids and give it another scrub.

I’m not really worried about terpenes.

Ever tried it with just keif?

Oh yeah

definitely vs defiantly

Hi. My question is, can I use dry ice kife for extraction instead of flowers.

Please comment. Thanks

Yes. Same process

Thank you very much

Made the tincture yesterday following your instructions – it’s excellent. Ended up with light yellow (maybe slightly more yellow than yours, because I’ve shaken it a bit more and squeezed a bit more), very potent tincture. I’ve decided to use it as is, and evaporate the second wash, as it felt very sticky and will probably yield enough for some butter/oil/dabbing material. I’ve used 27g GSC, decarbing inside a jar, and 96% ethanol, also 5kg dry ice which was too much. I’m not a fan of dabbing, but I really wanted “purest” tincture I could make, and I think this is it. The smell is insane as well, I don’t think it lost anything, it smells like extremely concentrated GSC. Taste is decent, not at all what would you expect, it’s actually sweet, no bitter plant taste at all.

That right there is the craft my friend. Sounds like you nailed it

Do you recommend using more than 20ml ethanol:1gram with dry ice? I live in poland and ethanol is cheap for me (not even 15$ per 500ml, and i can get it even cheaper). I would like to get as much as possible in first run and avoid second, third wash but would adding ethanol change yield?

It’s more a factor of proper coverage than dedicated ration as a lot of the ethanol may be diverted to dead space for fluffy material or minimized for dense material. It depends and it part of the art

So you say it’s impossible to avoid need for second run (wash) as with first run i can dissolve no more than 80% thc/cannabinoids (unless i stir a lot and introduce waxes etc to liquid, or make undabbable “feco”). More ethanol doesnt change anything, right?

Everything to deal with that is in the “Extraction and Yield: It’s a Balance” post

Loved this article and it was very informative… answered quite a few questions in my head.

I am curious as to whether or not you have used “wet cured” cannabis with this method to limit undesirables as well.

I have not. I think others have in the past but I don’t remember the feedback being great. With proper material prep and temp/time management in making the wash, additional steps aren’t really necessary.

Instead of agitation by shaking the jar periodically over the 30 minute wash, I am planning to do the wash in a 2L ultrasound cleaner positioned in my freezer and filled with pure ethanol and buds frozen from fresh. The trichome heads that do not dissolve may break off from their stems and be carried away when the solvent is separated from the plant material. Please comment

It seems human nature to always try to go one step further. Using ultrasonics for the wash is both unnecessary and disadvantageous. It is unnecessary because ethanol is aggressive enough on its own to collect what needs collecting.

More importantly, the ultrasonics will equally disturb the undesirables we are working against with the cold temp wash. It will lead to cell structure penetration.

Essentially, I would suggest that you misunderstand the purpose of agitation and mistakenly substitute and supposedly improve the process with ultrasonics. The agitation is simply for moving ethanol around the material so fresh ethanol can replace any boundary layer type saturation that may happen. It’s just a movement of fluid. Ultrasonics, on the other hand, are much more into material disruption, which you don’t want to subject an ethanol wash to.

I work with very high-power ultrasonic equipment and am quite familiar with it. Take my word for it when I say it’s just the wrong tool for the wrong reason. This article is a bit older. The Ethanol Extraction: Complete Breakdown post is a bit newer if you’d like to take a look there about prep and wash steps.